Common Misconceptions About Chainmail Aprons

Common Misconceptions About Chainmail Aprons

When purchasing chainmail for protection or display, I often struggle to know which products are genuinely high-quality. Whether I’m looking for chainmail for an industrial job, cosplay, or as a collectible, it’s easy to get overwhelmed by the variety of products out there. If you’re like me, you’ve probably wondered: Is this chainmail apron really up to the task? Can I trust it for heavy-duty use, or is it just a decorative piece? These questions are more common than you might think, especially when you’re shopping for products like chainmail aprons, which are critical for both safety and durability in many industries.

But fear not! Understanding what to look for in chainmail isn’t as complicated as it may seem. In fact, with a few simple steps, you can easily differentiate between high-quality chainmail products and those that may not live up to their claims. Let’s dive into some common misconceptions about chainmail aprons and uncover how you can evaluate their true quality. By the end of this article, you’ll be equipped to make informed decisions and ensure that any chainmail purchase meets your needswhether you’re working in a professional kitchen or creating an authentic cosplay look.

Common Pain Points When Buying Chainmail

1. Differentiating Between Welded and Open Rings

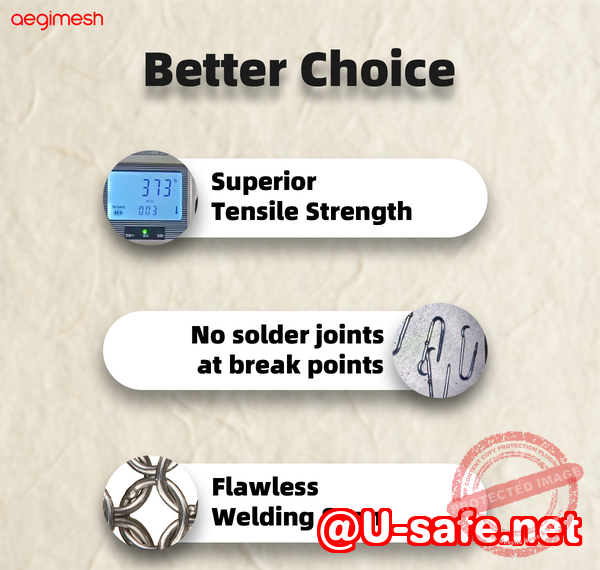

One of the most frequent issues people face when evaluating chainmail products is distinguishing between welded rings and open rings. You may see the term “welded” used in product descriptions, but how can you be sure? Open ringsthose that are simply twisted together without weldingare typically weaker and more prone to coming undone. This is a problem for anyone using chainmail for protective purposes, such as in industrial settings.

2. Uncertainty About Stainless Steel Grades

Not all stainless steel is created equal. When it comes to chainmail, the grade of stainless steel used can make all the difference in durability and corrosion resistance. Many chainmail products are made from 304 stainless steel, but when it comes to industrial use or long-lasting wear, you might want to opt for 316 stainless steel, which offers superior resistance to corrosion. The question is, how can you tell which grade is used in your chainmail product? Some manufacturers don’t provide this detail, but it’s essential to know before making your purchase.

3. Weak or Inconsistent Weaves

Another challenge when evaluating chainmail is ensuring the weave pattern is consistent and strong. Weave patterns like the European 4-in-1 are popular for a reasonthey provide a good balance of flexibility and strength. However, not all chainmail weaves are created equal. A poor-quality weave can result in gaps or weak spots that compromise the effectiveness of the chainmail for both protective and aesthetic purposes.

How to Inspect Chainmail Quality

The good news is that inspecting chainmail for quality doesn’t require any special skills. With a few simple checks, you can quickly assess whether a product is worth your investment.

1. Inspect the Material

Start by checking the material. As mentioned earlier, stainless steel is the preferred material for most high-quality chainmail. You’ll typically encounter two main grades: 304 and 316. Both are durable, but 316 stainless steel is highly resistant to corrosion and is ideal for industrial use, especially in food processing or environments where the chainmail will be exposed to moisture. To ensure you’re getting the right grade, ask the manufacturer for more details, or use a magnet to check304 is magnetic, but 316 isn’t.

2. Evaluate the Ring Welding

Welded rings are critical for the durability of chainmail, especially when used in industrial or safety settings. Open rings, on the other hand, might look similar at first glance but can easily come undone under pressure. To check the welding, gently tug on a few rings. If they feel loose or come apart, you’re dealing with open rings that could compromise the effectiveness of the chainmail.

3. Check Wire Thickness and Ring Diameter

The thickness of the wire used in the rings, as well as the inner diameter of the rings, also play a significant role in the strength and flexibility of the chainmail. Thicker wire and smaller ring diameters generally result in stronger chainmail, especially when paired with a solid weave pattern. A good rule of thumb is to ensure the rings feel solid and robust when you handle them. If they bend or deform easily, it’s a sign the chainmail may not be up to the task.

4. Assess the Weave Pattern

The European 4-in-1 weave is often used for high-quality chainmail because it offers a great balance between flexibility and strength. In this pattern, each ring is connected to four others, forming a stable and durable grid. When inspecting a product, check for evenness in the weave. Irregularities or gaps could indicate poor craftsmanship, which might lead to weaker protection or reduced durability.

Why Chainmail Quality Matters

The importance of inspecting chainmail goes beyond simply making sure it looks good. Whether you’re using it for industrial protection, cosplay, or as part of a historical costume, the quality of the chainmail can have significant safety and durability implications.

1. Safety Concerns

For industrial use, especially in food processing or meat handling, the chainmail you choose must be cut-resistant. Low-quality chainmail made from weak rings or poor welds could easily fail in high-stress situations, leaving you exposed to injury. A proper inspection ensures that you’re investing in chainmail that offers the protection you need.

2. Durability for Long-Term Use

Even for decorative or cosplay purposes, durability matters. You don’t want your chainmail to fall apart after just a few uses, especially if it’s meant to be worn or displayed frequently. By checking the material, welds, and weave, you ensure your chainmail will hold up over time.

3. Cost-Effectiveness

No one wants to waste money on a subpar product. By following these inspection steps, you can identify low-quality chainmail before making a purchase. This allows you to avoid making an unsafe or wasteful purchase and helps you find chainmail that meets your needs at a fair price.

Key Takeaways and Recommendations

When purchasing chainmail, it’s essential to inspect the material, welds, wire thickness, ring diameter, and weave pattern to ensure you’re getting a high-quality product. Don’t be afraid to ask questions, especially about the grade of stainless steel and the welding process. I highly recommend following these steps to ensure any chainmail purchase meets safety and durability standards.

Take action today:

Learn more about identifying high-quality chainmail products: Aegimesh Chainmail Inspection Guide. Check out our detailed chainmail inspection guide to ensure you’re making the right choice.

Perguntas frequentes

1. How can I tell if a chainmail ring is welded or open?

Welded rings are typically more durable and secure. To check, gently tug on a few rings. If they stay intact, the rings are welded. If they come apart or feel loose, they’re likely open rings.

2. Which stainless steel grade is best for long-lasting chainmail?

For industrial and heavy-duty use, 316 stainless steel is the best choice due to its superior corrosion resistance. For decorative or lighter use, 304 stainless steel can be sufficient.

3. How do I inspect the weave pattern for strength?

Look for an even, consistent weave pattern like the European 4-in-1. This weave is known for its strength and flexibility. Irregularities or gaps in the weave are signs of poor craftsmanship.

4. What are the signs of low-quality or unsafe chainmail?

Signs of low-quality chainmail include loose rings, inconsistent weave patterns, weak or thin wire, and visible signs of corrosion or damage.

5. Can decorative chainmail be used for protective purposes?

While decorative chainmail can look impressive, it may not offer the same level of protection as chainmail designed specifically for safety. Always check the material and welds before using it for protective purposes.

6. How do I choose the right chainmail for industrial vs cosplay use?

For industrial use, prioritize durability and protection by selecting chainmail made with high-quality stainless steel, welded rings, and a sturdy weave pattern. For cosplay, focus on aesthetics and comfort, ensuring the chainmail fits your costume design.

7. What’s the best way to maintain chainmail over time?

Regularly inspect your chainmail for signs of wear, clean it properly to avoid corrosion, and store it in a dry place to ensure it lasts for years.