Exploring the Long-Term Benefits of EN 1082-Certified Chainmail Gear

Exploring the Long-Term Benefits of EN 1082-Certified Chainmail Gear

When it comes to purchasing chainmail for protection or display, it’s easy to feel overwhelmed. Whether you’re a cosplayer, industrial worker, or collector, finding high-quality chainmail that offers both safety and durability can be a challenge. I’ve been there myselflooking through endless online listings, wondering how to tell the difference between genuine, long-lasting chainmail and cheaper, less reliable alternatives. What’s the real difference between welded rings and open rings? How do you know if you’re getting a durable weave? And most importantlyhow can you avoid the unsafe, low-quality chainmail that could let you down when you need it most?

In this post, I’m going to walk you through how to evaluate chainmail, particularly focusing on how to identify EN 1082-certified products, like Aegimesh Chainmail, that stand up to both safety and durability standards. By the end of this guide, you’ll feel confident in your ability to assess chainmail quality and make informed decisions for your personal or professional needs.

The Chainmail Dilemma: Understanding Common Pain Points

I get itchainmail can be tricky to evaluate at first glance. When you’re faced with a sea of products online, it can be tough to know what’s genuinely high-quality. Let’s break down the most common pain points I’ve encountered, and I’m sure you’ve faced as well:

-

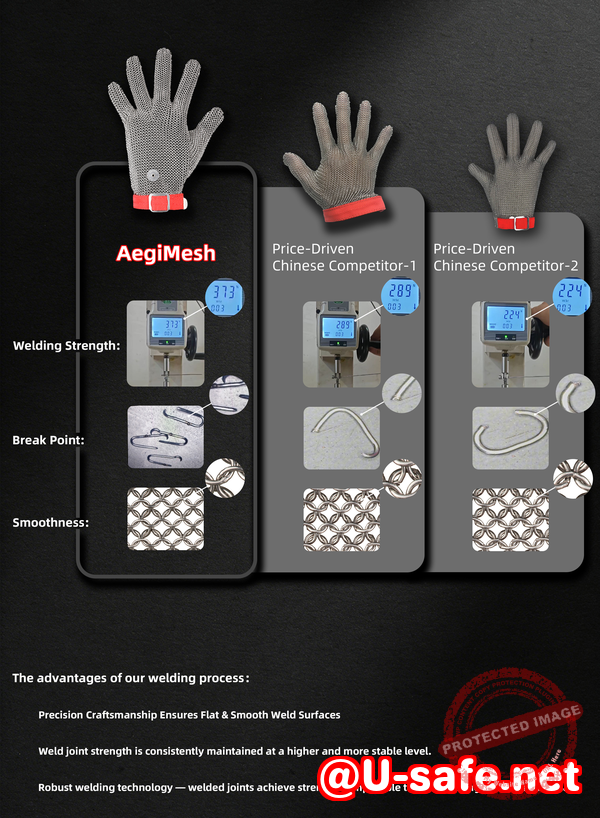

Welded vs. Open Rings: The distinction between welded and open rings is one of the most confusing parts of chainmail inspection. Open rings, while cheaper, can easily become undone, compromising the overall durability. Welded rings, on the other hand, provide a secure link that holds up better over time and under stress.

-

Corrosion Resistance & Material Quality: Stainless steel is a common material used in chainmail, but not all stainless steel is created equal. You might find products made from 304 stainless steel, which is good but may not offer the best resistance to corrosion, especially in humid or food-processing environments. Then there’s 316 stainless steel, which is superior in terms of corrosion resistanceespecially in harsh industrial settings.

-

Weak or Inconsistent Weaves: Chainmail is all about the weave, and not all weaves are equal. A poorly done weave, whether it’s a 4-in-1 European weave or something else, can result in inconsistent protection. A weak weave means more gaps, less durability, and an overall unsafe product.

But don’t worry, these issues are easily avoidable if you know what to look for.

The Solution: How to Inspect Chainmail Like a Pro

The key to avoiding poor-quality chainmail and ensuring you get the best value for your money lies in a proper inspection. Here are the steps you should follow to evaluate the quality of any chainmail you’re considering for purchasewhether it’s for personal, professional, or cosplay use.

1. Check the Material: 304 vs 316 Stainless Steel

Not all stainless steel is created equal, and it’s important to know the difference between 304 and 316 stainless steel. While 304 is a standard, cost-effective option for chainmail, 316 offers superior corrosion resistance, making it ideal for environments where moisture or chemicals are a concernsuch as food processing, medical applications, or industrial settings.

-

304 Stainless Steel: This is a common grade for general-purpose chainmail. It offers decent resistance to corrosion but may not hold up well in harsh environments.

-

316 Stainless Steel: If you need something more durable and resistant to rust, 316 stainless steel is the way to go. It’s more resistant to chlorides (salt), making it an excellent choice for coastal areas or for use in food handling.

2. Inspect the Rings: Welded vs Open

One of the easiest ways to tell if chainmail is of good quality is by checking the rings. Welded rings are the gold standard, as they are permanently closed, ensuring the weave won’t come undone over time. If the rings are open, they can easily separate, especially under pressure. This compromises the safety and effectiveness of the chainmail.

-

How to check: Run your finger along the rings. If they feel smooth and secure, with no visible gap or seam, you’re likely dealing with welded rings. Open rings will feel less secure and might have a slight gap or rough edge where they’re joined.

3. Evaluate Wire Thickness & Inner Diameter

The wire thickness and inner diameter of the rings play a crucial role in the durability and strength of the chainmail. Thicker wire means stronger chainmail, while thinner wire could result in a weaker, more flexible material that may not provide the protection you need.

-

Wire Thickness: Thicker wire generally equates to stronger chainmail, capable of withstanding more wear and tear. But be carefultoo thick of wire could make the chainmail stiff and less comfortable to wear. A good balance is essential.

-

Inner Diameter: A larger inner diameter can lead to a looser weave, which may weaken the structure. Smaller diameters result in a denser weave and stronger protection.

4. Assess the Weave Pattern: European 4-in-1 and Beyond

The weave pattern is crucial to the overall strength of chainmail. The European 4-in-1 weave is one of the most common and reliable weaves used for protection, as it provides a dense, interconnected structure that is resistant to both cuts and impacts.

-

How to check: Inspect the weave closely. You should see a neat, even interlocking pattern. Any irregularities or gaps in the weave could indicate poor craftsmanship or a low-quality product.

5. Perform the Pull Test

To test the strength of the chainmail, you can do a simple pull test. Grab a section of the chainmail and gently pull on the rings. If they feel loose or shift under pressure, it’s a red flag. High-quality chainmail should stay in place without any noticeable stretching or bending.

Why It’s Important to Inspect Chainmail Thoroughly

Investing in high-quality chainmail comes with multiple benefits:

-

Safety: Especially for industrial or food-related use, it’s critical that your chainmail is made from strong, corrosion-resistant materials and uses durable, welded rings. Subpar chainmail could expose you to serious injuries or contamination risks.

-

Durability: A proper inspection helps ensure that the chainmail will last over time, whether you’re using it for work or as part of a costume. By avoiding low-quality products, you’re saving money in the long run, as you won’t need to replace worn-out gear.

-

Peace of Mind: Knowing that your chainmail is made from high-quality materials, with a reliable weave and durable construction, gives you confidence. Whether you’re in an industrial setting or attending a cosplay event, you can feel secure knowing your gear will perform as expected.

Conclusion: How to Buy Chainmail with Confidence

After following these steps to inspect chainmail, I can confidently say that you’ll be able to avoid the pitfalls of poor-quality products. When it comes to Aegimesh Chainmail, for instance, you can rest assured that the rings are welded, the material is high-grade stainless steel (316 for maximum corrosion resistance), and the weave is tightly constructed for durability and safety.

I highly recommend following these inspection steps before making any chainmail purchase, whether it’s for safety, cosplay, or collection. By taking the time to assess the quality, you’ll save money and ensure your chainmail will stand up to whatever challenge you put it through.

Learn more about identifying high-quality chainmail products: https://www.aegimesh.com/

Check out our detailed chainmail inspection guide today.

Perguntas frequentes

-

How can I tell if a chainmail ring is welded or open?

Simply check the ringswelded rings will feel smooth and secure, while open rings will have a visible gap.

-

Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel offers superior corrosion resistance, making it the best choice for industrial use and food processing.

-

How do I inspect the weave pattern for strength?

Look for an even, tight interlocking pattern. The European 4-in-1 weave is a strong, reliable choice for protection.

-

What are the signs of low-quality or unsafe chainmail?

Poor craftsmanship, irregular weaves, open rings, or thin wire are signs of low-quality chainmail that might compromise safety.

-

Can decorative chainmail be used for protective purposes?

While decorative chainmail may look good, it often lacks the durability and strength needed for protection. Make sure to choose certified, industrial-quality chainmail for safety.

-

How do I choose the right chainmail for industrial vs cosplay use?

For industrial use, opt for thicker wire and corrosion-resistant 316 stainless steel. For cosplay, aesthetic appeal may be more important, so focus on the visual design, but still check the weave and ring quality.

Tags or Keywords

-

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability