Why EN 1082 Is Critical for Workplace Safety Gear

Why EN 1082 Is Critical for Workplace Safety Gear

When it comes to workplace safety, especially in industries where cuts and abrasions are common, one protective gear option that stands out is chainmail. Whether it’s for food processing, industrial work, or even cosplay, knowing how to distinguish high-quality chainmail can be a game-changer. But with so many options available, how can you be sure you’re choosing the right one?

A lot of buyers, whether they’re industrial users, collectors, or even cosplayers, face the same challenge: how to evaluate chainmail effectively to ensure it’s durable, safe, and up to standard. That’s where understanding EN 1082 standards comes in.

The Role of EN 1082 in Workplace Safety

EN 1082 is a set of European standards specifically designed to assess the effectiveness of chainmail used for cut-resistant gear. In other words, this standard helps ensure that the chainmail you use, whether it’s for industrial purposes, food processing, or even just a costume, offers the level of protection you need.

But why should you care about these standards?

Let’s start with a real-world example.

Imagine you’re working in a high-risk environment, like a butcher’s shop or an industrial warehouse, where sharp objects are common. You’re wearing a chainmail glove to protect your hands, but halfway through your shift, the glove starts to tear or become loose. That could be a disaster in the making, right?

The same goes for cosplayers or historical reenactors who may wear chainmail armor for authenticity but aren’t sure if it’s truly durable for long wear. If you don’t know how to evaluate the quality of the chainmail, you’re potentially putting yourself at risk.

The good news is that by following the right guidelines, like the EN 1082 standard, you can avoid these problems. Understanding key features such as welded rings, wire thickness, and weave patterns will help you determine whether a piece of chainmail is truly high-quality or just a decorative imitation.

Pain Points: What Buyers Face When Choosing Chainmail

For anyone buying chainmail, whether for safety or aesthetic purposes, the biggest challenge is identifying a high-quality product. Some of the common issues include:

-

Welded vs Open Rings

When you’re looking at chainmail, it’s crucial to know whether the rings are welded or open. Welded rings are far more durable and provide better protection against cuts than open rings. Unfortunately, many sellers cut corners and sell chainmail made with open rings, which are not as strong or reliable.

-

Stainless Steel Grades

Stainless steel is often used in chainmail, but not all stainless steel is created equal. Grades like 304 and 316 have different properties, including resistance to corrosion. If you’re buying chainmail for use in wet or harsh environments, you’ll want to ensure it’s made from the right grade. If the chainmail uses lower-grade steel, you could run into corrosion or rust problems.

-

Weave Inconsistencies

The strength of chainmail depends largely on the weave pattern. For example, European 4-in-1 is one of the most robust weave patterns, offering excellent protection and durability. Weave inconsistencies, such as mismatched ring sizes or improper tension, can compromise the effectiveness of the chainmail.

Aegimesh Chainmail: Your Guide to High-Quality Protection

At Aegimesh, we understand how important it is to know what you’re buying when it comes to chainmail. That’s why we’ve created a detailed guide to help you evaluate chainmail quality. We cover everything from identifying welded rings to checking the material grade and inspecting the weave patterns. Here’s how to ensure your chainmail is up to par:

-

Material Type (304 vs 316 Stainless Steel)

The material used in chainmail plays a huge role in its durability. 304 stainless steel is good for general use but is prone to corrosion in wet environments. 316 stainless steel, on the other hand, is highly resistant to corrosion, making it ideal for environments like food processing or coastal areas where moisture is a concern. Always check the grade of steel used in your chainmail.

-

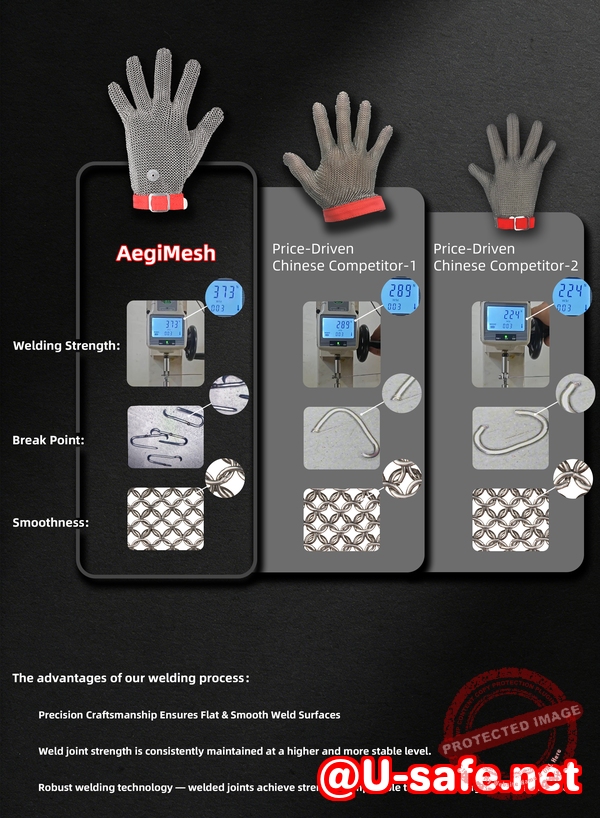

Ring Welding

One of the easiest ways to spot high-quality chainmail is by checking the rings. High-quality chainmail uses welded rings, which provide a stronger, more durable connection between each ring. Open rings, on the other hand, are weaker and more likely to come apart, leading to potential safety risks.

-

Wire Thickness and Ring Diameter

Stronger chainmail typically uses thicker wire and larger rings. The wire thickness contributes to the overall strength of the material, while the ring diameter can affect how flexible the chainmail is. If you’re buying chainmail for industrial use, you’ll want thicker wire and smaller rings to maximize protection. For cosplay or decorative use, the choice of wire thickness and ring diameter may be more flexible, but it still affects durability.

-

Weave Patterns: The European 4-in-1 Weave

European 4-in-1 is one of the most common and effective chainmail weaves. It involves each ring passing through four other rings, providing a tight, interlocking structure that offers excellent protection. When evaluating chainmail, check the consistency of the weave to ensure the rings are tightly interwoven and that the pattern is not loose or poorly constructed.

How to Inspect Your Chainmail: Step-by-Step

When it comes to inspecting chainmail, here’s a quick guide on what to look for:

-

Perform a Pull Test

One of the simplest ways to check the durability of chainmail is by pulling on the rings. If they move too easily or feel loose, the chainmail is likely of low quality.

-

Look for Signs of Corrosion

Especially with food handling or industrial-grade chainmail, corrosion is a major concern. Inspect for any rust or discoloration, which can indicate poor steel quality or exposure to moisture.

-

Examine the Weave Consistency

Check that the weave is consistent. Each ring should be firmly connected to the next, with no gaps or slack. If you spot uneven weaving, it could signal that the chainmail won’t hold up under pressure.

-

Match the Type to the Task

Different types of chainmail are suited for different uses. For example, industrial workers need chainmail that offers maximum cut protection, while cosplayers might prioritize authenticity and flexibility. Make sure the chainmail you choose fits the task at hand.

Conclusion: Why EN 1082 Matters for Your Safety

When shopping for chainmail, whether for work or recreation, it’s crucial to take the time to inspect the material, welding, and weave pattern. The EN 1082 standard provides a framework for ensuring that your chainmail offers the protection and durability you need.

I highly recommend following these steps to ensure any chainmail purchase meets safety and durability standards. By knowing what to look for, you can avoid unsafe purchases, save money, and enjoy peace of mind knowing that your chainmail will perform when you need it most.

Learn more about identifying high-quality chainmail products: Aegimesh Chainmail Inspection Guide

FAQ

-

How can I tell if a chainmail ring is welded or open?

Inspect the rings closely. Welded rings will have a visible join where the metal is fused, while open rings will have a gap where they meet.

-

Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel is the best choice for environments with moisture or high corrosion risk, offering long-lasting durability.

-

How do I inspect the weave pattern for strength?

Look for consistency in the weave. European 4-in-1 is a common strong pattern where each ring connects to four others.

-

What are the signs of low-quality or unsafe chainmail?

Signs include loose rings, inconsistent weaving, signs of corrosion, or a flimsy overall feel when handled.

-

Can decorative chainmail be used for protective purposes?

Decorative chainmail is generally not suitable for safety purposes due to weaker materials and construction. Always choose industrial-grade chainmail for protective uses.

-

How do I choose the right chainmail for industrial vs cosplay use?

For industrial use, prioritize strong, durable materials like welded rings and 316 stainless steel. For cosplay, focus on comfort and appearance but ensure the chainmail is well-made.

-

Is there a simple test to check chainmail quality?

Yes! You can perform a simple pull test by gently pulling on the rings. If they come apart or feel weak, the chainmail might not be durable enough for its intended use.

Tags/Keywords

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability