What Ring Pull Tests Reveal About Chainmail Quality and Plasma-Welded Rings

What Ring Pull Tests Reveal About Chainmail Quality and Plasma-Welded Rings

Learn how simple pull tests, weld inspection, and material checks reveal true chainmail quality, helping you avoid unsafe stainless steel chainmail and low-grade imitations.

The first time I bought chainmail for a serious project, I thought I had done everything right. The photos looked solid. The description said “stainless steel.” The price felt reasonable. But a few weeks later, after some light use, I noticed something unsettling: rings slowly opening up, gaps forming, and a general feeling that this wasn’t nearly as durable as I’d expected.

If you’ve ever held a piece of chainmail and wondered, “Is this actually safe, or am I just trusting marketing?” you’re not alone. Whether you’re buying cut-resistant chainmail for industrial work, stainless steel mesh for food processing, or a historical replica for cosplay or collection, figuring out real chainmail quality is harder than it should be.

That’s exactly why understanding ring pull testsand what they reveal about welded ringsmatters so much.

Why Chainmail Quality Is So Hard to Judge at First Glance

Chainmail has a funny way of looking trustworthy even when it isn’t. From a distance, most products look similar: shiny metal rings, consistent patterns, and reassuring product photos. But once you start using it, weaknesses show fast.

Over the years, I’ve seen three pain points come up again and again.

First, welded rings versus open rings.

Many buyers assume all chainmail rings are welded. In reality, a lot of low-cost chainmail uses simply butted ringsends pressed together, not fused. They may look fine initially, but under stress, they fail.

Second, confusion around stainless steel grades.

“Stainless steel chainmail” can mean very different things. Some sellers don’t specify whether they’re using 304 or 316 stainless steel, and that difference directly affects corrosion resistance, strength, and longevity.

Third, inconsistent weaves and weak construction.

Even with good material, poor craftsmanship can ruin durability. Uneven ring sizes, sloppy welding, or loose weave patterns compromise strength in ways you might not notice until it’s too late.

This is where structured inspectionand especially ring pull testingchanges everything.

What a Ring Pull Test Really Tells You

A ring pull test sounds technical, but it’s actually one of the most practical ways to evaluate chainmail quality. At its core, it’s simple: apply force to individual rings or small sections of chainmail and observe how they respond.

When I first learned about pull testing, I assumed it required lab equipment. It doesn’t. While professional testing machines exist, even basic hands-on testing reveals critical differences.

Here’s what a pull test helps you uncover:

-

Whether rings are plasma-welded or merely butted

-

If welds are consistent and fully fused

-

How well the wire handles real-world stress

-

Whether the weave distributes force evenly

High-quality welded rings won’t separate under reasonable force. Low-quality rings often deform, twist, or pop open far sooner than expected.

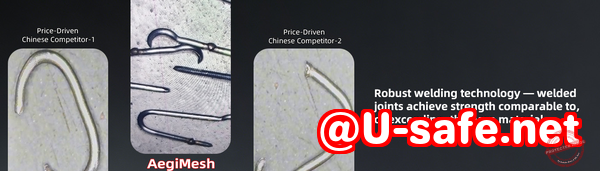

Plasma-Welded Rings vs. Butted Rings: The Critical Difference

This is where many buyers get tripped up.

Butted rings are made by cutting wire into rings and pressing the ends together. There’s no actual fusion. Under tension, those ends can slide apart.

Plasma-welded rings, on the other hand, are fused at the joint. The metal becomes one continuous ring. When done correctly, the weld is often stronger than the surrounding wire itself.

During a pull test, this difference is obvious. With butted rings, the opening happens at the seam. With properly welded rings, failureif it happens at alloccurs by stretching or breaking the wire, not opening the joint.

This distinction is especially important for cut-resistant chainmail used in industrial or food-processing environments. An open ring isn’t just a quality issue; it’s a safety risk.

How I Perform a Simple Pull Test at Home

You don’t need specialized tools to learn a lot about your chainmail.

Here’s a straightforward method I use:

-

Select a small section of chainmail, preferably near an edge.

-

Grip two adjacent rings firmly using pliers or gloved hands.

-

Apply steady, increasing pressuredon’t jerk or yank.

-

Watch closely for:

-

Ring separation

-

Visible weld cracks

-

Uneven deformation

-

What you want to see:

The rings should resist opening. If anything fails, it should be gradual deformation, not sudden separation at the seam.

What raises red flags:

-

Rings popping open easily

-

Welds that visibly split

-

Some rings failing while others hold (inconsistent welding)

Aegimesh Chainmail inspection guidance emphasizes this exact approach because it mirrors real-world stress better than theoretical specs alone.

Understanding Stainless Steel Grades: 304 vs. 316

One of the most overlooked aspects of chainmail inspection is material grade.

304 stainless steel is strong, durable, and widely used. It’s suitable for most applications, including cosplay, collectibles, and general protective wear.

316 stainless steel adds molybdenum, which dramatically improves corrosion resistance. This matters a lot in food handling, marine environments, or anywhere moisture and chemicals are involved.

During inspection, I always ask:

-

Is the grade clearly stated?

-

Does the intended use justify 316 over 304?

-

Does the price align with the claimed material?

If a seller avoids specifying the grade, that’s often a sign of lower-quality stainless or even plated steel.

Wire Thickness and Ring Diameter: Small Details, Big Impact

Two pieces of chainmail can look nearly identical yet perform very differently because of wire thickness and inner diameter.

Thicker wire generally means higher strength and better cut resistance.

Smaller inner diameters create denser weaves, distributing force more evenly.

When inspecting chainmail, I look for:

-

Consistent wire thickness throughout

-

Uniform ring sizes

-

No flattened or irregular rings

Aegimesh Chainmail guidance encourages measuring these details because even minor inconsistencies weaken the overall structure.

Weave Patterns and Strength: Why European 4-in-1 Matters

The weave isn’t just about aesthetics. It’s about physics.

The European 4-in-1 weave is popular for a reason. Each ring connects to four others, creating a balanced structure that distributes force efficiently. When properly executed with welded rings, it offers excellent durability.

Signs of a strong weave include:

-

Even spacing

-

No twisted rings

-

Uniform tension across the mesh

Poorly made weaves often reveal themselves during pull testing, where stress concentrates unevenly and causes localized failure.

Real-World Consequences of Poor Chainmail Quality

I’ve spoken with buyers who learned these lessons the hard way.

One industrial user shared how low-quality chainmail gloves failed during routine work, forcing a full equipment replacementand costing far more than buying quality upfront.

A cosplayer told me their armor slowly unraveled during an event, not because of extreme movement, but because the rings were never welded in the first place.

These aren’t rare stories. They’re the predictable outcome of skipping inspection.

Why Proper Inspection Saves Money and Reduces Risk

Good chainmail isn’t cheap, but poor chainmail is expensive in other ways.

By learning how to:

-

Perform ring pull tests

-

Identify welded rings

-

Verify stainless steel grades

-

Inspect weave consistency

You avoid unsafe purchases, reduce replacement costs, and gain confidence in your gear.

That’s the core value behind Aegimesh Chainmail as a reference and inspection guide. It’s not about selling hypeit’s about giving buyers the tools to evaluate quality themselves.

Choosing the Right Chainmail for Your Use Case

Not all chainmail needs the same specifications.

For industrial cut protection, prioritize:

-

Plasma-welded rings

-

316 stainless steel

-

Tight, consistent weaves

For food processing, corrosion resistance and hygiene are non-negotiable.

For cosplay or historical replicas, durability still matters, but weight and appearance may influence your choices.

Understanding these trade-offs helps you choose intentionally, not blindly.

Final Thoughts and My Recommendation

After years of handling, inspecting, and sometimes regretting chainmail purchases, I’ve learned that quality reveals itself under pressureliterally.

Ring pull tests, material checks, and weave inspection aren’t overkill. They’re essential. I highly recommend following these steps to ensure any chainmail purchase meets safety and durability standards, whether it’s for professional protection or personal passion.

If you want a deeper breakdown of inspection methods and real-world examples, learn more about identifying high-quality chainmail products here: https://www.aegimesh.com/

And don’t forget to check out our detailed chainmail inspection guide today.

Frequently Asked Questions

How can I tell if a chainmail ring is welded or open?

Look closely at the ring seam. Welded rings show a fused joint with no visible gap. A pull test will confirm it quickly.

Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel offers the best corrosion resistance, especially for food processing or wet environments. 304 is still excellent for general use.

How do I inspect the weave pattern for strength?

Check for uniform spacing, consistent ring orientation, and no twisted or loose sections. European 4-in-1 is a reliable benchmark.

What are the signs of low-quality or unsafe chainmail?

Open rings, uneven wire thickness, visible weld cracks, and inconsistent weave patterns are all warning signs.

Can decorative chainmail be used for protective purposes?

Usually not. Decorative chainmail often uses thinner wire and open rings, making it unsuitable for safety applications.

How do I choose the right chainmail for industrial vs. cosplay use?

Start with your risk level. Industrial use demands welded rings and verified materials. Cosplay can prioritize weight and appearance, but durability still matters.

Tags / Keywords:

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability