How EN 1082 Chainmail Reduces the Risk of Workplace Injuries

How EN 1082 Chainmail Reduces the Risk of Workplace Injuries

When you think of chainmail, you might picture medieval knights clashing swords in a battlefield or cosplayers in elaborate costumes. But in today’s world, chainmail has found a practical purpose in workplaces where cut-resistant protection is essential. Whether it’s in industrial settings, food processing plants, or historical replicas, EN 1082 chainmail is a crucial safety tool. However, not all chainmail products are created equal. So, how can you identify high-quality, safe, and durable chainmail that will genuinely reduce the risk of workplace injuries? Let’s take a closer look at how to evaluate chainmail quality and avoid unsafe products.

A Common Dilemma: Is My Chainmail Safe and Durable Enough?

As a buyer, collector, or industrial user, you might have found yourself in this situation: You’re about to purchase chainmail for protection, cosplay, or as a collectible. But then doubt creeps in. How can you be sure that the product is made of high-quality material? Will it stand up to wear and tear, especially in a workplace environment where safety is paramount?

These concerns are common, and rightfully so. Poor-quality chainmail can cause injuries instead of preventing them. A weak weave or subpar material can compromise its effectiveness, putting workers and users at risk. So, how do you know you’re getting a chainmail product that’s worth your investment?

The good news is, there are clear ways to assess the quality of chainmail products. Here’s where Aegimesh’s guide to chainmail inspection comes in handy. By following a few simple steps, you can ensure that your purchase meets high safety and durability standards, whether you’re buying it for industrial use, historical re-enactment, or even as part of a cosplay costume.

Common Chainmail Pitfalls: Identifying Low-Quality Products

Let’s dive into the common pitfalls you might encounter when evaluating chainmail and how to avoid them.

1. Distinguishing Between Welded and Open Rings

One of the most important aspects of chainmail is the construction of the rings. You may come across two types of chainmail rings: welded and open. While open rings can be cheaper and look similar, they don’t offer the same level of protection. A welded ring is a solid choice because it ensures the durability of the weave. Open rings, on the other hand, can come apart under stress, rendering the chainmail less effective at protecting against cuts.

Tip: Always check whether the rings are welded. A quick look under magnification will help you spot the seam where the ring has been welded shut. If there’s no seam, chances are the rings are open.

2. Choosing the Right Stainless Steel Grade

When it comes to stainless steel, not all grades are the same. The most commonly used grades in chainmail are 304 and 316 stainless steel. While both are durable and resistant to corrosion, 316 stainless steel is the superior option, especially for environments where the chainmail will be exposed to harsh conditions like salty air or chemicals. This is why it’s the preferred material for food processing industries.

Tip: Always verify the grade of stainless steel used. 304 is good for most industrial applications, but for marine environments or food processing, opt for 316 for its superior corrosion resistance.

3. Weak or Inconsistent Weaves

A poorly woven chainmail product can cause significant problems. For instance, uneven or loose weaves can lead to gaps where the protective properties of the chainmail fail. European 4-in-1 is a popular and strong weave pattern that is highly recommended for both strength and flexibility. A solid weave pattern ensures that the chainmail will perform as expected, even under stress.

Tip: Check the weave pattern for consistency. The European 4-in-1 is one of the most reliable options for cut-resistant chainmail, and it’s essential to inspect that the rings are securely linked.

How to Inspect and Verify Chainmail Quality

Now that we’ve discussed common pain points, let’s explore how you can inspect chainmail products and make sure they meet the safety standards required for your intended use.

1. Check the Material Type

When inspecting chainmail, start with the material. Look for clear labeling that identifies the type of stainless steel used. If you’re unsure, ask the supplier or manufacturer for clarification. Both 304 and 316 stainless steel are durable, but remember, 316 is your best bet for corrosion resistance in harsh environments.

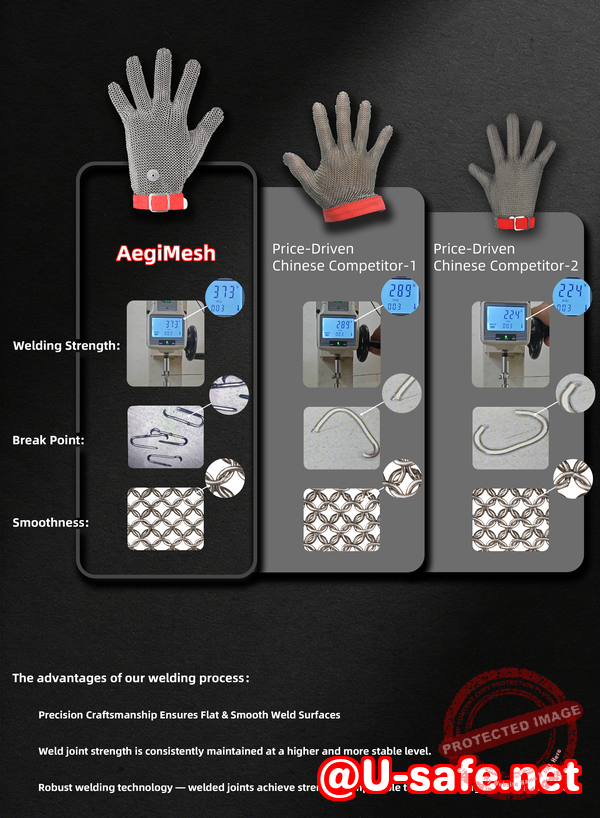

2. Inspect the Ring Welding

As mentioned earlier, welded rings are a must for durability. The welding should be smooth, with no visible gaps or breaks. Use a magnifying glass to check the edges of the rings. If they seem flimsy or the seam is visible, the rings might be of poor quality.

3. Evaluate the Ring Diameter and Wire Thickness

The diameter of the rings and the thickness of the wire play a significant role in the chainmail’s overall strength. For industrial or protective use, thicker wire and a larger diameter ensure better durability. Use calipers or a ruler to measure the rings and compare them against the manufacturer’s specifications.

4. Perform the Pull Test

For a simple yet effective test of the chainmail’s strength, try a pull test. Grasp the chainmail in two hands and give it a firm pull. High-quality chainmail should be able to withstand tension without the rings breaking apart or the weave loosening. If the material feels fragile or comes apart too easily, it’s likely not a safe choice for protection.

5. Inspect for Corrosion or Signs of Wear

For stainless steel chainmail, corrosion is a significant concern, especially in environments where exposure to moisture is common. Check for any signs of rust or discoloration. If the chainmail has been poorly maintained or made with low-quality stainless steel, it may already show early signs of deterioration.

Why Proper Chainmail Inspection Matters

Properly inspecting chainmail doesn’t just save you moneyit can also prevent injuries. Whether you’re buying chainmail for industrial use, food processing, cosplay, or as a collectible, ensuring the product meets high standards is essential.

Here are some benefits of investing time in chainmail inspection:

-

Safety Assurance: Low-quality or poorly constructed chainmail won’t provide the protection it promises, putting workers or users at risk.

-

Cost Savings: By identifying low-quality chainmail before purchase, you can avoid wasting money on products that won’t last.

-

Durability: High-quality chainmail can last for years, even in tough environments, saving you from frequent replacements.

Conclusion: A Simple Approach to Choosing Quality Chainmail

In summary, inspecting chainmail might seem like a daunting task, but it doesn’t have to be. By following these simple inspection methods, you can identify high-quality products that will keep you safe, whether at work or in your personal collections.

I highly recommend taking the time to inspect any chainmail before making a purchase. Look for welded rings, verify the stainless steel grade, check the weave pattern, and conduct a pull test. These steps will ensure that your chainmail is as safe and durable as possible.

Want to dive deeper into the world of chainmail? Learn more about identifying high-quality chainmail products and check out our detailed inspection guide today.

Visit us at Aegimesh Chainmail to start making informed choices for your next purchase.

Frequently Asked Questions (FAQs)

How can I tell if a chainmail ring is welded or open?

Look closely at the ring. Welded rings will have a visible seam where the ends are joined, while open rings will not be sealed and can pull apart easily.

Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel is superior for resisting corrosion, especially in harsh environments. However, 304 stainless steel works well for general industrial use.

How do I inspect the weave pattern for strength?

Check for consistency and tightness in the weave. The European 4-in-1 pattern is a strong and reliable option for durability and flexibility.

What are the signs of low-quality or unsafe chainmail?

Signs include weak or open rings, inconsistent weave patterns, rust or discoloration, and flimsy material that doesn’t pass the pull test.

Can decorative chainmail be used for protective purposes?

While decorative chainmail may look appealing, it often doesn’t provide the same level of protection as industrial-grade chainmail. Be sure to verify the product’s strength before use in a safety-critical environment.

How do I choose the right chainmail for industrial vs cosplay use?

For industrial use, opt for chainmail made from high-quality 316 stainless steel with a strong, tight weave. For cosplay, aesthetic qualities may be more important, but make sure the product is still durable enough to withstand handling.

Tags or Keywords

-

chainmail quality

-

welded rings

-

stainless steel chainmail

-

cut-resistant chainmail

-

chainmail inspection

-

European 4-in-1 weave

-

chainmail durability