Chainmail Aprons for Food Processing Plants

Chainmail Aprons for Food Processing Plants: How to Choose the Best for Safety and Durability

When it comes to food processing, safety is paramount. Workers in these environments face numerous risks, from sharp knives to heavy machinery, making protective gear essential. Chainmail aprons are a popular choice for food processing plants because they provide a high level of cut protection. However, not all chainmail is created equal. It can be difficult to tell whether you’re getting a high-quality apron that offers real protection or a decorative piece that’s more style than substance. That’s where knowing what to look for comes inwhether you’re purchasing for industrial use, cosplay, or historical reenactments.

I’ve had my fair share of confusion when shopping for chainmail, and I know I’m not alone. With so many options available, how do you know which ones will stand up to the test in high-risk environments like food processing? In this guide, I’ll walk you through how to spot the difference between high-quality chainmail and low-quality or unsafe products. You’ll leave with practical tips to ensure your purchase is both durable and safe.

Common Pain Points When Buying Chainmail

When it comes to evaluating chainmail, several common issues can arise, especially for first-time buyers or those unfamiliar with the finer details of construction. Here are some pain points that I’ve noticedand I’m sure you have too:

-

Welded Rings vs. Open Rings

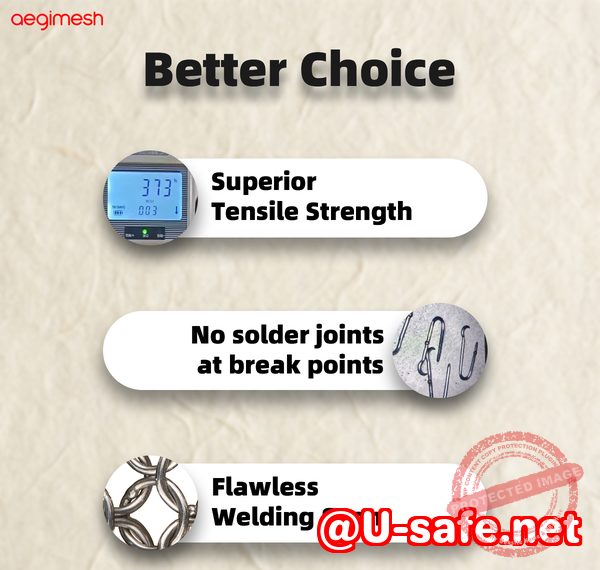

It’s easy to overlook, but the type of rings used in chainmail can make or break its durability. Welded rings are much stronger and more reliable than open rings, which are often used in lower-quality chainmail. The strength of welded rings ensures that the chainmail apron can stand up to the rigors of food processing, whereas open rings may cause the apron to unravel over time.

-

Stainless Steel Grades

Not all stainless steel is created equal. For long-lasting durability and resistance to rust or corrosion, you need to choose the right grade. While 304 stainless steel is decent for many applications, 316 stainless steel is a better option, especially in food processing, where moisture and exposure to acidic foods could quickly degrade lower-quality metals.

-

Weave Patterns

The strength of a chainmail apron doesn’t just depend on the materialit’s also about the way it’s woven. Weave patterns like European 4-in-1 are ideal for strength and flexibility, but not all chainmail manufacturers use these high-quality patterns. A weak or inconsistent weave could compromise the apron’s ability to protect against cuts and abrasions.

How to Inspect Chainmail for Quality

Now that we’ve covered the pain points, let’s dive into how you can inspect chainmail products to ensure you’re getting the best of the best. Follow these simple steps to evaluate chainmail before you buy:

1. Material Type: 304 vs. 316 Stainless Steel

Start by inspecting the material. You want to ensure that the chainmail is made from high-quality stainless steel, with 316 stainless steel being the ideal choice for food processing environments. 316 steel offers superior resistance to corrosion, which is crucial in high-moisture or acidic environments like kitchens or food processing plants.

-

304 Stainless Steel: Suitable for general purposes but less resistant to corrosion than 316.

-

316 Stainless Steel: Best for environments exposed to moisture or corrosive substances.

2. Check the Ring Welding

Examine the rings closely to see if they are welded or open. Welded rings are much more durable and provide a better seal, ensuring the chainmail holds up over time. Open rings may look similar but are less reliable and prone to falling apart.

-

Welded Rings: Secure and durable.

-

Open Rings: Less durable, prone to loosening.

3. Inspect Wire Thickness and Inner Diameter

The thickness of the wire and the inner diameter of the rings play a significant role in the strength of the chainmail. For chainmail used in industrial settings, the wire should be thick enough to withstand heavy wear and tear, and the inner diameter of the rings should be small enough to prevent cuts from slipping through.

-

Thicker Wire: Stronger and more durable.

-

Tighter Ring Diameter: Provides better protection against cuts.

4. Weave Pattern European 4-in-1

The weave pattern is another critical factor in determining the strength of the chainmail. European 4-in-1 is the most commonly used weave pattern for protective chainmail. It involves weaving each ring through four others, creating a tight and secure pattern that offers maximum protection.

-

European 4-in-1: Standard for strength and durability.

-

Other Weaves: May not offer the same level of protection.

5. Perform a Pull Test

A simple pull test can help you evaluate the quality of the chainmail. Take a section of the apron and pull the rings. If the rings hold firm and the weave doesn’t loosen, you’ve got yourself a high-quality product. If the rings shift or the weave loosens, this could indicate poor craftsmanship.

-

Firm Weave: Indicates good craftsmanship.

-

Loose Weave: Sign of low-quality production.

6. Look for Signs of Corrosion

Even stainless steel can develop rust over time if exposed to the wrong conditions. Always check for any signs of corrosion or rust spots, especially around the rings. If you notice any discoloration or rough patches, this could indicate the chainmail is of low quality or that it hasn’t been treated properly.

Benefits of Proper Chainmail Inspection

Taking the time to inspect your chainmail before purchasing can save you a lot of trouble down the line. Here’s why proper inspection matters:

-

Safety: Chainmail aprons are often worn in high-risk environments, like food processing plants, where safety is critical. Weak or poorly made chainmail can fail to protect workers from cuts and injuries.

-

Durability: A quality apron can last for years, providing reliable protection. Poor craftsmanship or low-quality materials, on the other hand, can result in a short lifespan.

-

Cost Savings: By identifying low-quality products before you buy, you can avoid wasting money on subpar chainmail that needs to be replaced sooner than expected.

Conclusion: Choose the Right Chainmail for Your Needs

In conclusion, purchasing high-quality chainmail is not as straightforward as it might seem, but with the right knowledge, you can make an informed decision. Whether you’re looking for industrial cut protection, food handling gear, or cosplay pieces, it’s essential to inspect the material, welds, wire thickness, and weave patterns to ensure the product will serve its intended purpose.

I highly recommend following these steps to ensure any chainmail purchase meets safety and durability standards. Whether for protection in a food processing plant or as part of your costume collection, chainmail is an investment in your safety and enjoyment.

Learn more about identifying high-quality chainmail products: Aegimesh Chainmail

Check out our detailed chainmail inspection guide today.

FAQ

-

How can I tell if a chainmail ring is welded or open?

Inspect the ring closely; welded rings will have a smooth, sealed edge, while open rings will have a visible gap.

-

Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel is ideal for long-lasting chainmail, especially in food processing environments due to its superior corrosion resistance.

-

How do I inspect the weave pattern for strength?

Look for a tight, consistent weave like European 4-in-1. This pattern ensures the chainmail holds together under stress.

-

What are the signs of low-quality or unsafe chainmail?

Look for loose rings, inconsistent weaving, rust, or rings that are not welded securely.

-

Can decorative chainmail be used for protective purposes?

While decorative chainmail can look great for cosplay, it may not provide the necessary strength or durability for industrial or protective use.

-

How do I choose the right chainmail for industrial vs. cosplay use?

For industrial use, prioritize durability and strength by selecting welded, thick wire chainmail made from 316 stainless steel. For cosplay, focus on appearance and comfort, but still ensure the chainmail is made from quality materials.

-

Why is European 4-in-1 the preferred weave pattern?

The European 4-in-1 weave provides the best combination of strength, flexibility, and protection. Each ring is securely locked in place, making it ideal for both safety and aesthetics.

Tags: chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability