How EN 1082 Helps Manufacturers Produce High-Quality Chainmail

How EN 1082 Helps Manufacturers Produce High-Quality Chainmail

When you’re on the hunt for high-quality chainmail, whether for industrial use, cosplay, or historical reenactments, it’s easy to feel overwhelmed by the variety of products on the market. I’ve been there myself examining several chainmail options and wondering which ones will actually hold up over time. After all, it’s not just about appearance. The material, craftsmanship, and strength of the chainmail can make a huge difference in its safety and durability.

In this article, I’ll walk you through some practical tips for inspecting and evaluating chainmail based on industry standards particularly the EN 1082 certification. Let’s dive into how manufacturers use these standards to produce high-quality chainmail products and what you, as a buyer or user, should be looking for when making your purchase.

Why Chainmail Quality Matters: A Real-Life Scenario

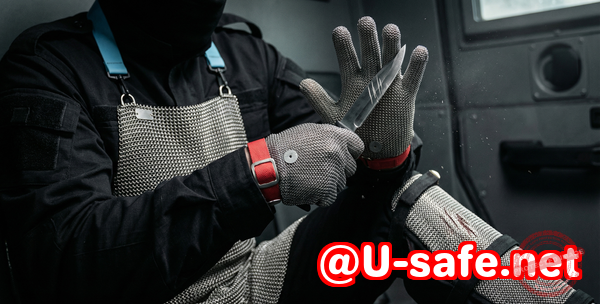

Picture this: You’re purchasing a suit of chainmail for a food processing plant, where workers handle sharp materials like knives or broken glass. It’s not just a decorative piece it’s meant to protect someone from serious cuts. Now, imagine that the chainmail you purchased turns out to be poorly constructed, with open rings instead of welded ones, thin wire that can snap under pressure, or a weave pattern that doesn’t provide enough protection. Suddenly, what was supposed to keep someone safe is a risk in itself.

This scenario happens more often than you might think, especially when buyers fail to properly evaluate the chainmail they’re purchasing. Whether for industrial use, cosplay, or even historical reenactments, it’s important to understand how to identify genuine, durable chainmail from low-quality or decorative imitations. Let’s break down what to look for.

Understanding EN 1082: The Standard for Quality Chainmail

EN 1082 is a European standard that sets guidelines for the manufacture of chainmail used in protective gear, especially for preventing cuts. Manufacturers who comply with EN 1082 are held to a high standard of quality, ensuring that their products provide adequate protection against sharp objects. These guidelines cover everything from material choice to ring welding to weave patterns. But how does this affect you, the buyer?

When you understand how EN 1082 affects chainmail production, you’re better equipped to evaluate whether a product meets safety and durability standards. Here’s a quick overview of the key areas EN 1082 focuses on:

-

Material Quality: Stainless steel, particularly grades 304 and 316, are the best choices for chainmail because they resist corrosion and maintain their strength over time.

-

Welded vs. Open Rings: The rings of the chainmail should be welded, not just bent. Welded rings provide significantly better durability and resistance to breakage.

-

Weave Patterns: The weave pattern, like European 4-in-1, is essential for providing strength and flexibility. A poorly woven chainmail suit can lead to gaps and weak points.

-

Wire Thickness: Thicker wire is more durable and resistant to damage, providing better protection.

How to Inspect and Evaluate Chainmail

So, how can you make sure the chainmail you’re purchasing meets these standards? There are a few practical methods to inspect and verify the quality of chainmail before making a purchase.

1. Check the Material

The material of the chainmail is the first thing you should check. If you’re looking for long-lasting, cut-resistant chainmail, the best options are stainless steel grades 304 and 316. Grade 304 is resistant to corrosion and good for most environments, but if you’re working in a harsher environment (like food processing or industrial settings), you may want to opt for 316, which is more resistant to corrosion.

2. Inspect the Rings: Welded vs. Open

One of the most common mistakes buyers make is not distinguishing between welded and open rings. Open rings may look fine at first glance, but they are far less durable and more prone to breakage. The rings should be welded shut to prevent them from opening over time and to ensure the chainmail stays intact. Here’s how to check:

-

Feel the ring edges: If you can feel a seam or gap, the ring is likely open.

-

Look for a clean weld: Welded rings should have a smooth, seamless join. There should be no visible gap or seam.

3. Wire Thickness and Inner Diameter

Wire thickness is another important factor to consider. Thicker wire means more durability, but it can also affect the flexibility and weight of the chainmail. You want a good balance between protection and comfort.

Additionally, the inner diameter of the rings should be consistent. If the rings are too wide or too narrow, it can impact the overall strength and flexibility of the chainmail. To check this:

-

Compare the rings: Use a micrometer or caliper to measure the wire thickness and inner diameter.

-

Look for uniformity: If the rings vary in size, the chainmail might not be as durable or protective.

4. Weave Pattern: European 4-in-1

The weave pattern is essential for the strength of the chainmail. The European 4-in-1 weave is one of the most popular patterns because it provides excellent flexibility and strength. In this pattern, each ring passes through four other rings, creating a tight and secure weave. To check the pattern:

-

Look for consistency: Make sure the pattern is uniform throughout the chainmail.

-

Check for gaps: If there are visible gaps between rings, the weave is likely not strong enough for protective use.

5. Perform a Pull Test

A simple but effective way to check the durability of chainmail is to perform a pull test. Hold a section of the chainmail and apply pressure to see if the rings hold together. If they bend or break, the chainmail is likely of low quality.

6. Look for Signs of Corrosion or Poor Craftsmanship

Corrosion can be a sign that the chainmail is not made of high-quality stainless steel or has been poorly maintained. Look for any rust spots or signs of wear and tear. Also, inspect the weave to make sure that there are no loose rings or uneven sections.

Key Benefits of Proper Inspection

By following these simple inspection methods, you can avoid making a costly mistake. Whether you’re buying chainmail for industrial safety, cosplay, or historical reenactment, inspecting your chainmail helps you:

-

Ensure Safety: For industrial or food processing use, poor-quality chainmail can pose a serious safety risk.

-

Guarantee Durability: Well-made chainmail will last longer and offer better protection.

-

Save Money: Identifying low-quality chainmail early saves you from wasting money on products that don’t perform as expected.

Conclusion: My Recommendation

When it comes to chainmail, I highly recommend following these inspection steps to ensure that your purchase meets both safety and durability standards. Whether you’re looking for protective gear, cosplay materials, or a historical replica, it’s crucial to make an informed decision. After all, chainmail is an investment in safety and quality and it should be treated as such.

To learn more about how to identify high-quality chainmail products and avoid low-quality imitations, check out our detailed guide on chainmail inspection at Aegimesh Chainmail. It’s your one-stop resource for everything chainmail.

FAQ

-

How can I tell if a chainmail ring is welded or open?

-

Feel the edges of the ring. If you feel a seam or gap, it’s an open ring. Welded rings should have no visible seam.

-

-

Which stainless steel grade is best for long-lasting chainmail?

-

For most uses, grade 304 is sufficient. However, for harsher environments (e.g., food processing), grade 316 is more durable and corrosion-resistant.

-

-

How do I inspect the weave pattern for strength?

-

Look for a consistent European 4-in-1 pattern without gaps between rings. This weave is strong and flexible.

-

-

What are the signs of low-quality or unsafe chainmail?

-

Weak welds, inconsistent wire thickness, open rings, and gaps in the weave all signal poor-quality chainmail.

-

-

Can decorative chainmail be used for protective purposes?

-

Not always. Decorative chainmail might not be as durable or resistant to cuts. For protective purposes, always ensure the chainmail meets industrial standards.

-

-

How do I choose the right chainmail for industrial vs. cosplay use?

-

For industrial use, prioritize strength, durability, and proper material like stainless steel grades 304 or 316. For cosplay, you can focus more on appearance, but ensure it’s still durable enough for your needs.

-

Tags or Keywords

-

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability