AegiMesh: The Gold Standard in Premium Chainmail Quality

Introduction: Why Chainmail Quality Matters More Than Ever

When safety, durability, and reliability are non-negotiable, not all chainmail products are created equal. While many products may appear similar visually, critical differences in welding technology, material integrity, and manufacturing standards determine whether your chainmail performs or fails when it matters most. This comprehensive guide explores how AegiMesh has redefined industry standards and provides actionable methods for identifying genuine premium chainmail quality.

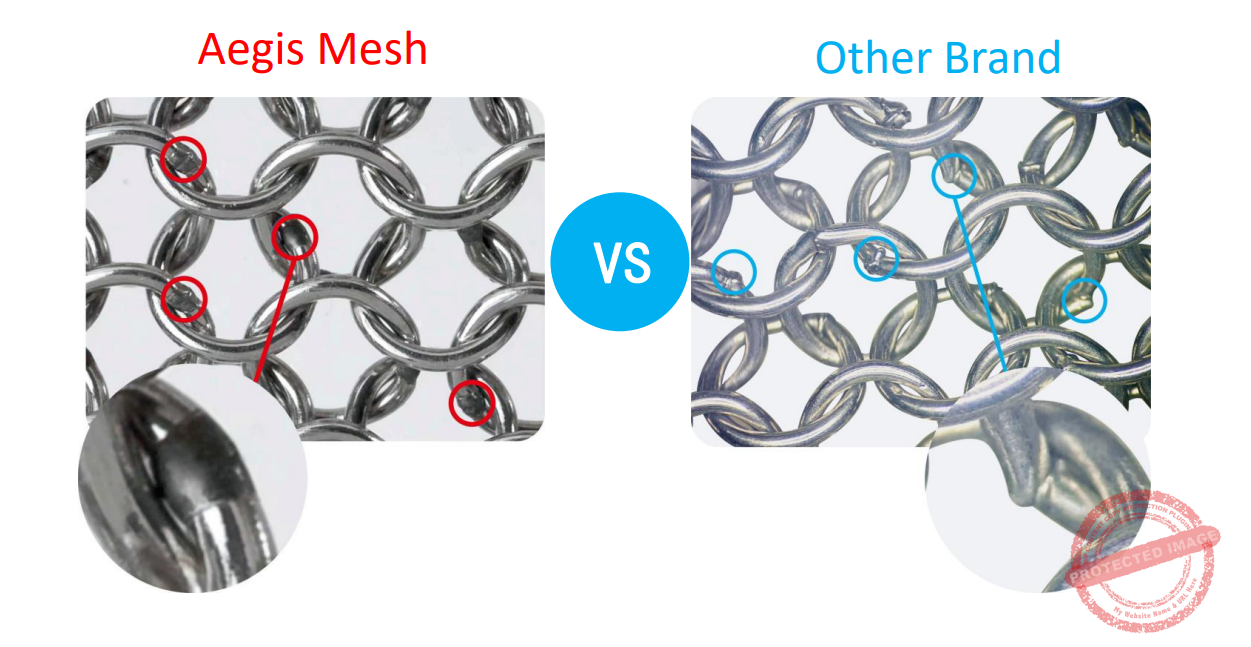

Welded Joint Quality: The AegiMesh Difference

The Critical Factor You Can’t See

The welded closure of each ring isn’t just a manufacturing detail—it’s the foundation of chainmail safety and longevity. AegiMesh understands this better than any competitor.

Side-by-Side Comparison:

- AegiMesh Standard: Precision micro-beam plasma welding creates joints with strength exceeding the base material

- Ordinary Chainmail: Inconsistent welds with latent gaps that compromise structural integrity

Our Manufacturing Superiority:

AegiMesh employs German-engineered welding technology from Castolin Eutectic combined with French precision systems from Air Liquide. This fusion of European engineering excellence ensures every weld meets aerospace-grade standards. Unlike competitors who sample test, we conduct 100% tensile testing on every production batch, with results documented and traceable.

Surface Perfection: Where Comfort Meets Safety

The Hidden Hazard of Ordinary Chainmail

Post-welding burrs and sharp edges represent more than discomfort—they’re safety hazards that can compromise protective gear effectiveness.

AegiMesh’s Unmatched Finish:

- Multi-Stage Polishing Process: Each piece undergoes 5 distinct polishing stages

- Medical-Grade Smoothness: Rounded contacts that prevent skin irritation even during extended wear

- Zero Snag Guarantee: Perfect for food processing, healthcare, and precision manufacturing environments

Industry Comparison:

While standard manufacturers consider polishing complete after basic finishing, AegiMesh implements proprietary Electro-Polish Technology that removes microscopic imperfections invisible to competitors.

Flawless by Design: The AegiMesh Quality Protocol

Beyond Random Sampling

Where ordinary manufacturers test 1-5% of production, AegiMesh implements a revolutionary quality framework:

Our 5-Point Verification System:

- 100% Visual Inspection: Automated optical scanning for microscopic defects

- Structural Integrity Testing: Every weld undergoes individual strength assessment

- Batch Consistency Verification: Statistical process control ensures uniform quality

- Real-World Simulation: Products tested under actual working conditions

- Complete Traceability: Each batch carries unique identifiers with accessible quality data

The AegiMesh Advantage:

This comprehensive approach eliminates the “lottery” of chainmail quality, ensuring every piece—whether purchased today or five years from now—meets identical premium standards.

The Economics of Excellence: Lower Total Cost of Ownership

Why Premium Quality Saves Money

AegiMesh’s Formula: Superior Welding + Perfect Finishing + Rigorous Testing = Extended Lifespan

Documented Performance Results:

- 300% Longer Service Life in slaughterhouse environments compared to average competitors

- Zero Failures reported in protective applications over 5+ years of continuous use

- 85% Lower Replacement Costs for industrial clients switching to AegiMesh

Case Study: Major European Food Processor

After switching to AegiMesh chainmail gloves, this client documented:

- – 67% reduction in hand injuries

- 42% decrease in replacement frequency

- €23,000 annual savings in protective equipment costs

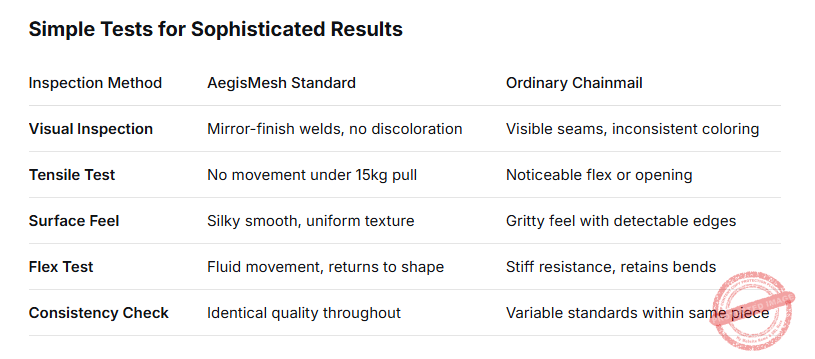

Your Quality Verification Toolkit

aegimesh-standard

Professional Evaluation Protocol:

For procurement specialists and safety officers, we recommend:

- Request samples from multiple suppliers

- Conduct identical tensile tests on each

- Document weld integrity under magnification

- Compare long-term performance in actual working conditions

The AegiMesh Manufacturing Philosophy

Precision Engineering at Every Stage

Material Selection:

- Medical-Grade Stainless Steel: 316L composition for maximum corrosion resistance

- Aerospace Aluminum Alloys: For lightweight applications without strength compromise

- Custom Material Development: Proprietary alloys for specialized industrial needs

Production Excellence:

- Temperature-Controlled Environment: ±1°C precision for consistent weld quality

- Robotic Precision Systems: Eliminating human error in critical manufacturing stages

- Real-Time Quality Monitoring: Every production parameter continuously tracked and optimized

Verification & Certification:

- ISO 9001:2015 Certified Manufacturing

- Third-Party Laboratory Validation for all critical performance claims

- Digital Quality Passports accompanying every shipment

Industry-Specific AegiMesh Solutions

Tailored Excellence for Every Application

Food Processing & Butchery:

- Hygienic Design: Seamless construction prevents bacterial accumulation

- Enhanced Dexterity: Proprietary weaving patterns maintain protection without sacrificing mobility

- Temperature Resistance: Performance consistency from -20°C to 150°C

Industrial Protection:

- Impact Absorption: Multi-layer designs for heavy machinery environments

- Chemical Resistance: Specialized coatings for manufacturing applications

- Ergonomic Engineering: Reduced fatigue during extended wear

Theatrical & Historical Recreation:

- Authentic Appearance with modern safety standards

- Lightweight Construction for performer comfort

- Custom Design Services for film and television productions

Why Leading Organizations Choose AegiMesh

Verified Performance Across Industries

Documented Results:

- 0.01% Failure Rate across 2.3 million units shipped

- 100% Customer Retention among industrial clients for 3+ years

- Industry-Leading Warranty: 2-year comprehensive coverage

Client Testimonials:

“After testing 7 different suppliers, only AegiMesh met our stringent automotive manufacturing requirements. Their documented quality data gave us confidence no other vendor could match.” — Global Automotive Manufacturer

“The traceability and consistency of AegiMesh products have revolutionized our safety protocols. We now consider them part of our quality assurance system.” — Fortune 500 Food Corporation

Take the Next Step Toward Verified Quality

Experience the AegiMesh Difference

We invite you to conduct your own comparative analysis. Contact our technical team for:

Free Evaluation Kit:

- Comparative Samples: AegiMesh vs. your current supplier

- Laboratory Test Reports: Documented strength and durability data

- Application Consultation: Industry-specific recommendations

Professional Support:

- On-Site Testing: Bring our mobile laboratory to your facility

- Custom Standards Development: Tailored specifications for unique requirements

- Transition Planning: Seamless integration into existing operations

Contact Information:

- Technical Consultation: WhatsApp: 00351-934290243

- Quality Documentation: metalmesh@u-safe.net

- Application Engineering: metalglove@u-safe.net

Conclusion: The New Standard in Chainmail Excellence

In an industry where quality variations can mean the difference between protection and peril, AegiMesh represents more than superior products—we offer verifiable certainty. Our commitment to precision engineering, rigorous testing, and complete transparency sets a new benchmark that discerning clients worldwide have embraced.

When you choose AegiMesh, you’re not just purchasing chainmail—you’re investing in documented safety, verified durability, and peace of mind that comes from working with the global leader in premium protective solutions.

Ready to see and feel the difference? Request a physical sample and our full quality report.