EN 1082 and Its Importance in Protecting Workers from Sharp Objects

EN 1082 and Its Importance in Protecting Workers from Sharp Objects

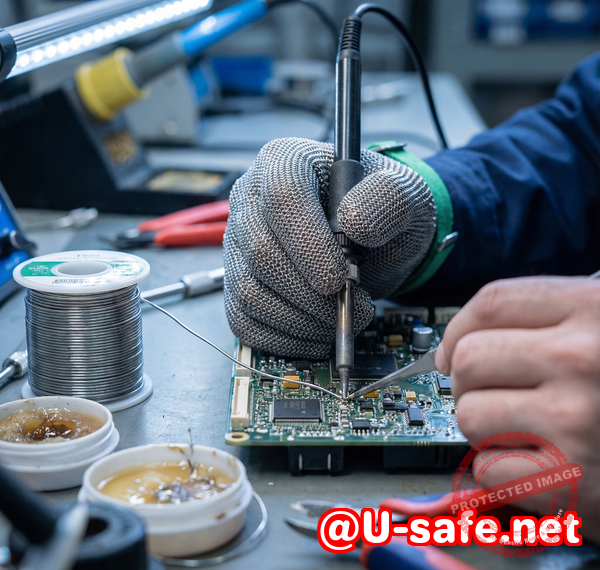

When you work with sharp objects dailywhether in food processing, industrial environments, or historical reenactmentsthe risk of injury is always a concern. As someone who’s spent time evaluating chainmail products for safety and durability, I’ve seen firsthand how difficult it can be to choose high-quality protection. For many buyers, whether they’re looking for industrial safety gear, cosplay accessories, or decorative pieces, distinguishing between high-quality and low-quality chainmail can be a challenge. One thing that can make this easier is understanding key safety standards like EN 1082, which helps guide us toward reliable products.

Chainmail has a long history of offering protection against sharp objects. But with so many options on the market today, how do you know you’re getting the best quality for your specific needs? I’ll walk you through some essential steps you can take to evaluate chainmail, and why EN 1082 should be on your radar.

The Chainmail Challenge: What Buyers Struggle With

When purchasing chainmail for protection or display, many buyers are concerned about two things: safety and durability. In an industrial setting, especially when handling sharp objects like knives or machinery, chainmail needs to be more than just a historical costume pieceit must protect against severe cuts and injuries. However, a lot of products out there are poorly made or designed purely for decoration.

I’ve often heard complaints from industrial buyers about not being able to distinguish quality chainmail from lower-grade options. For example, a buyer might want to purchase stainless steel chainmail for protection against industrial blades but ends up with a cheap alternative that offers little protection.

That’s why knowing how to evaluate the materials, design, and overall craftsmanship of the chainmail is critical.

EN 1082: A Standard That Can Save Lives

EN 1082 is a European standard for chainmail, designed specifically to test the effectiveness of protective clothing against cutting injuries from sharp objects. This standard is essential for anyone purchasing chainmail for safety purposes. While EN 1082 certification isn’t the only factor to consider, it provides a solid foundation for assessing whether a chainmail product meets safety expectations.

As part of EN 1082 certification, manufacturers must demonstrate that their chainmail can withstand a specific force and resist cuts from sharp objects. The performance requirements cover both the material and the construction, ensuring the rings are welded properly, the wire is thick enough, and the weave pattern provides adequate protection.

By choosing chainmail that complies with EN 1082, you can be more confident that it will meet the necessary strength and durability for your specific needs, whether it’s for food processing, industrial work, or protective wear.

The Aegimesh Chainmail Inspection Guide

Let’s dive into the practical steps of evaluating chainmail. I’ll break down key aspects like material quality, ring welding, weave patterns, and overall craftsmanship so you can make an informed decision.

1. Inspecting Material: Stainless Steel Grades (304 vs. 316)

Not all stainless steel is created equal. When evaluating chainmail, it’s important to check which grade of stainless steel has been used. The two most common grades are 304 and 316.

-

304 Stainless Steel: This is the most common and cost-effective option, offering decent corrosion resistance. However, it’s not the best choice for environments that involve frequent exposure to harsh chemicals or saltwater.

-

316 Stainless Steel: This grade provides superior resistance to corrosion, making it ideal for more demanding environments, such as industrial or food processing settings. If you’re working in a wet or high-humidity environment, 316 is the better choice.

2. Checking Ring Welding: Welded vs. Open Rings

One of the easiest ways to evaluate chainmail quality is to look at how the rings are connected. Quality chainmail should have welded rings, not open rings, as these are far more durable and secure.

-

Welded Rings: These are permanently fused together, offering greater strength and durability. When rings are welded, there’s less risk of them coming apart, especially under heavy stress or impact.

-

Open Rings: While cheaper, open rings are much weaker. They can often be pulled apart, which compromises the chainmail’s effectiveness in providing protection.

3. Assessing Weave Patterns: European 4-in-1 for Strength

Another key to evaluating chainmail is the weave pattern. Different weaves offer different levels of protection. The European 4-in-1 weave is a popular choice for both strength and flexibility. This pattern involves each ring passing through four others, which creates a dense, sturdy grid that can effectively stop sharp objects.

When inspecting the weave, check for consistency. A poorly woven pattern will leave gaps, reducing the chainmail’s overall effectiveness. Ideally, the weave should be tight enough to prevent any sharp object from slipping through.

4. Evaluating Wire Thickness and Ring Diameter

The wire thickness and inner ring diameter are also critical factors in determining the durability and strength of chainmail. The thicker the wire and the smaller the inner diameter of the rings, the stronger the chainmail will be. You’ll want to check that the wire isn’t too thin, as this can compromise its cut-resistance.

5. Performing Practical Tests: The Pull Test

To ensure that the chainmail is as durable as it should be, I recommend performing a pull test. Take a few rings and apply pressure to see if they come apart. If the rings hold under pressure, then you’re dealing with quality chainmail. If they bend or snap, it’s a clear sign of inferior craftsmanship.

Why This All Matters: Making Informed Choices

By taking the time to carefully inspect the chainmail, you can avoid making unsafe or costly purchases. Whether you’re choosing chainmail for industrial work, cosplay, or historical reenactments, following these inspection methods will help you find the right product for your needs.

Properly inspecting your chainmail ensures:

-

Safety: Industrial workers and food handlers need to ensure their gear provides reliable protection from sharp objects.

-

Durability: High-quality chainmail will last longer, saving you money in the long run.

-

Performance: Whether for decorative purposes or active use, chainmail that’s made to last will perform better in any scenario.

Conclusion: My Final Thoughts on Chainmail Evaluation

When it comes to buying chainmail, I highly recommend following these inspection steps. Whether you’re looking for protective wear for industrial use, food safety, or even for cosplay, evaluating material quality, ring welding, wire thickness, and weave patterns is essential for ensuring you get the best possible product.

Remember, investing a little extra time into checking the quality of your chainmail can save you from safety risks and wasted money down the line.

If you’re ready to make informed choices and ensure your purchases meet safety standards, take a look at Aegimesh Chainmail’s detailed inspection guide at www.aegimesh.com.

Preguntas frecuentes

-

How can I tell if a chainmail ring is welded or open?

-

To check, simply look for the point where the ring ends. Welded rings will have a smooth, seamless connection, while open rings will show a visible gap where they are closed.

-

-

Which stainless steel grade is best for long-lasting chainmail?

-

For most uses, 316 stainless steel is the best choice due to its superior corrosion resistance. If you’re on a budget, 304 is fine for less demanding environments.

-

-

How do I inspect the weave pattern for strength?

-

Look for a tight, uniform pattern. The European 4-in-1 weave is a common choice that ensures strength and flexibility, making it suitable for various uses.

-

-

What are the signs of low-quality or unsafe chainmail?

-

Weak or inconsistent weaves, thin wire, and open rings are all signs of low-quality chainmail. If the rings can be pulled apart or the weave is uneven, it may not provide adequate protection.

-

-

Can decorative chainmail be used for protective purposes?

-

Decorative chainmail is often not built to the same standards as industrial or protective chainmail. Always inspect for safety features like welded rings and appropriate materials if you plan to use it for protection.

-

-

How do I choose the right chainmail for industrial vs cosplay use?

-

For industrial use, prioritize durability, corrosion resistance, and strength. For cosplay, you may focus more on aesthetic appeal, but make sure the weave is strong enough to withstand wear and tear.

-

Tags or Keywords

-

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability