Why EN 1082-Certified Chainmail Is a Must for Professional Use

Why EN 1082-Certified Chainmail Is a Must for Professional Use

When you’re shopping for chainmail, whether it’s for safety on the job, a cosplay project, or a historical display, it’s easy to get lost in the sea of options available. You might have seen various chainmail pieces at a great price, or ones that seem too good to be true. But how can you tell if what you’re buying is genuinely high-quality? And more importantly, how can you be sure it’ll protect you or stand the test of time?

As someone who’s navigated the complexities of chainmail buying, I’ve learned that the difference between high-quality, durable chainmail and subpar imitations comes down to one key factor: certification and inspection. EN 1082-certified chainmail is your golden ticket to ensuring safety, longevity, and reliabilitywhether you need it for industrial use, food handling, cosplay, or even historical reenactments.

In this guide, I’m going to walk you through everything you need to know about choosing high-quality, certified chainmailhow to spot the good from the bad, and why an EN 1082 certification is crucial for professional use.

Common Pain Points When Evaluating Chainmail

If you’re like most buyers, you’ve probably run into a few frustrations when shopping for chainmail. Here are the most common pain points:

-

Identifying Welded vs. Open Rings: It’s easy to get confused between chainmail with welded rings (strong and durable) and those with open rings (often weaker and prone to unraveling).

-

Choosing the Right Stainless Steel: Not all stainless steel is created equal. Different grades can affect everything from the strength of the weave to the chainmail’s resistance to corrosion.

-

Weave Inconsistencies: If you’re buying chainmail for protective use, a weak or inconsistent weave can be a real safety issue. You need to ensure that the pattern is tight and uniform.

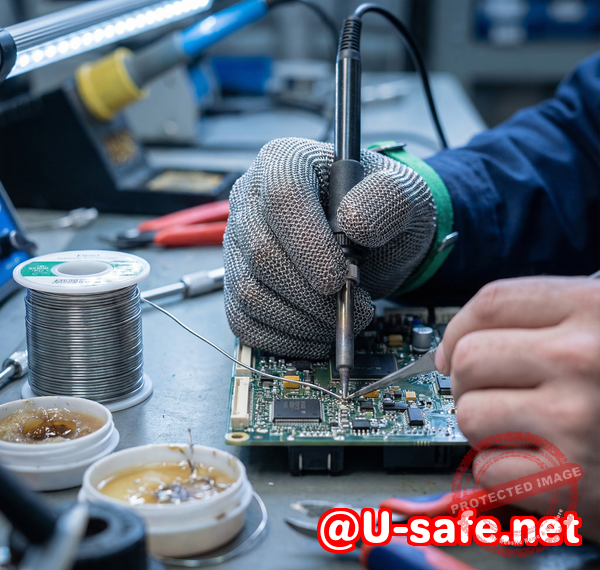

The Solution: Inspecting and Verifying Chainmail Quality

The key to buying high-quality chainmail lies in inspection. You don’t need to be an expert, but a little know-how goes a long way. Here’s what you should look for to ensure you’re getting chainmail that lives up to its promises:

1. Check the Material: Stainless Steel Grades Matter

The two most common types of stainless steel used in chainmail are 304 and 316. While both are corrosion-resistant and durable, 316 is typically considered superior, especially for environments that involve exposure to harsh chemicals or saltwater.

For industrial and professional use, you should always look for 316 stainless steel. It offers better resistance to corrosion, which is especially important if the chainmail will be exposed to moisture or high-heat conditions.

2. Inspect the Rings: Welded vs. Open

Chainmail rings come in two types: welded and open. Welded rings are the hallmark of quality chainmail because they are fused together to prevent the links from opening over time. This makes the chainmail stronger and more durable.

Open rings, on the other hand, are less secure and may fail under pressure. To check whether the rings are welded, simply look for a seam where the ring is joined. If there’s a noticeable gap or a poorly joined area, it’s likely open.

3. Evaluate the Weave Pattern: European 4-in-1 for Strength

The European 4-in-1 weave is one of the most popular and strongest patterns used in chainmail. In this weave, each ring passes through four others, which provides maximum flexibility while still maintaining its protective qualities.

If you’re buying chainmail for protective use, like cut-resistant chainmail, make sure the rings are tightly woven in a consistent pattern. You can perform a simple test by gently pulling the rings apart (without overstretching them) to see if the weave holds up. If it loosens or the rings shift too easily, it’s a sign the chainmail isn’t as durable as you need.

4. Check the Ring Thickness and Inner Diameter

Not all rings are made the same. The wire thickness and inner diameter of the rings will directly impact the durability of the chainmail. Thicker wires and smaller diameters tend to provide better protection, especially against sharp objects. For food handling or industrial applications, this is especially important to ensure maximum safety.

Why Aegimesh Chainmail Stands Out

At Aegimesh, we understand the importance of choosing high-quality chainmail. Our EN 1082-certified chainmail is designed to meet rigorous industry standards, ensuring your purchase is both reliable and safe. Whether you’re looking for cut-resistant chainmail for industrial use, chainmail for food processing, or durable pieces for cosplay or historical reenactments, we’ve got you covered.

By following our simple inspection guide, you can be sure that the chainmail you’re buying meets all the necessary standards for strength, durability, and safety.

Step-by-Step Guide to Inspecting Your Chainmail

To make the inspection process easier, follow these simple steps:

-

Look for the Certification: Always check if the chainmail has an EN 1082 certification, especially if it’s for industrial or professional use. This certification ensures the product meets European standards for strength, durability, and safety.

-

Check the Material: Determine whether the chainmail is made from 316 stainless steel. This material is the best for both industrial applications and environments where corrosion resistance is key.

-

Inspect the Welds: Gently examine the rings to ensure they are welded, not open. You can do this by lightly tugging on the rings. If they come apart easily, it’s a sign that the chainmail isn’t high-quality.

-

Evaluate the Weave: Ensure the European 4-in-1 weave is intact and consistent throughout the chainmail. This pattern offers the best balance between flexibility and strength.

-

Test Durability: Perform a simple pull test on the chainmail. If the weave holds together without stretching or falling apart, it’s likely high-quality.

Conclusion: Why EN 1082-Certified Chainmail Is Essential for Professional Use

When it comes to chainmail, choosing a high-quality product is crucialnot just for aesthetics, but for safety and durability. Whether you’re in an industrial setting, need cut-resistant protection for food handling, or simply want to create a durable cosplay or historical replica, the right chainmail makes all the difference.

I highly recommend following these steps to ensure any chainmail purchase meets safety and durability standards. By focusing on the material, weave, welds, and certification, you can avoid unsafe products and make an informed decision that will save you both time and money.

Learn more about identifying high-quality chainmail products: Aegimesh Chainmail

Frequently Asked Questions

1. How can I tell if a chainmail ring is welded or open?

Look closely at the seam. If you see a clean, fused joint, it’s likely welded. Open rings have a noticeable gap.

2. Which stainless steel grade is best for long-lasting chainmail?

For industrial or professional use, 316 stainless steel is the best choice due to its superior corrosion resistance.

3. How do I inspect the weave pattern for strength?

Check for the European 4-in-1 weave and ensure that the rings are tightly woven. The pattern should be consistent, and the rings shouldn’t shift easily when pulled.

4. What are the signs of low-quality or unsafe chainmail?

Look for poorly welded rings, loose or inconsistent weave patterns, and signs of corrosion or degradation, especially if the chainmail will be used in a harsh environment.

5. Can decorative chainmail be used for protective purposes?

Decorative chainmail is often made with open rings and weaker materials, so it’s not suitable for protection. Always choose EN 1082-certified chainmail for safety.

6. How do I choose the right chainmail for industrial vs. cosplay use?

For industrial use, opt for thicker wire, smaller inner diameters, and 316 stainless steel. For cosplay, 304 stainless steel may suffice, but ensure the rings are welded and the weave is tight.

Tags or Keywords

-

chainmail quality

-

welded rings

-

stainless steel chainmail

-

cut-resistant chainmail

-

chainmail inspection

-

European 4-in-1 weave

-

chainmail durability