How Steel Grade Impacts Steel Metal Chainmail Durability

How Steel Grade Impacts Steel Metal Chainmail Durability

When buying chainmail, whether for protection in industrial settings, for cosplay, or even as a historical replica, it can be hard to distinguish between high-quality products and cheaper, low-grade imitations. Have you ever found yourself second-guessing whether the chainmail you’re about to purchase is really going to hold up, or if it’s just a decorative piece that will fall apart after a few uses? If so, you’re not alone.

A lot of buyers, collectors, and professionals struggle with this. They often wonder: “How can I be sure this chainmail will withstand wear and tear?” “Is this really safe for industrial use?” The key to avoiding such doubts lies in understanding how steel grade impacts the durability of your chainmail.

Understanding the Role of Steel in Chainmail

Chainmail is an ancient protective garment, and today, it’s used for everything from historical reenactments to industrial cut protection. But what makes some chainmail tougher and more reliable than others? It all comes down to the quality of the steel used in its construction. The difference between steel grades, like 304 and 316 stainless steel, is crucial when determining whether the chainmail will stand up to daily wear and tear or if it’s more likely to corrode, break, or fail when you need it most.

In this guide, I’ll walk you through how to assess chainmail quality, focusing on the key factors that affect its durability. I’ll also share practical tips on how to inspect chainmail, whether you’re a collector, cosplayer, or industrial buyer looking to make an informed choice.

Common Pain Points When Buying Chainmail

There are several challenges that buyers face when purchasing chainmail. Let’s break down some of the most common ones.

1. Distinguishing Between Welded Rings and Open Rings

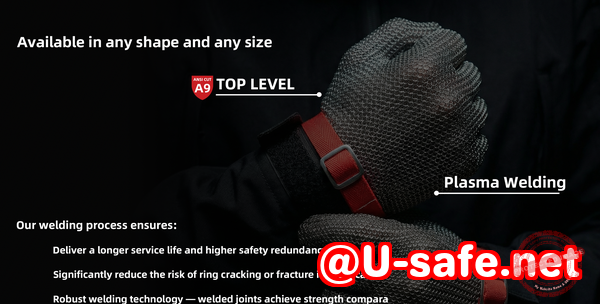

One of the most common mistakes I see buyers make is confusing welded rings with open rings. While open rings might look like chainmail at first glance, they simply won’t hold up under stress. Open rings can easily come apart, rendering the chainmail useless for protection or heavy-duty tasks.

Welded rings, on the other hand, provide much greater strength. When the rings are welded, they form a solid bond that resists separation even under significant force. Always look for the distinct seam on welded ringsthis is your assurance that the chainmail will stay intact, no matter what.

2. Confusion Over Steel Grades

When it comes to stainless steel chainmail, the grade of steel matters more than many realize. 304 stainless steel is great for decorative pieces, but it isn’t as resistant to corrosion as 316 stainless steel, which is more durable and corrosion-resistant. If you’re looking for chainmail that will hold up under harsh industrial conditions or even food processing environments, 316 steel is the better option.

It’s crucial to ask yourself: Will this chainmail be exposed to moisture or harsh chemicals? If yes, 316 stainless steel is your best bet for long-lasting durability. If it’s just for display or cosplay, 304 might be sufficient, but don’t compromise on quality when safety and performance are on the line.

3. Weak or Inconsistent Weaves

Another issue that often arises is inconsistent or poorly constructed weaves. A loose or weak weave can significantly reduce the chainmail’s durability. European 4-in-1 weave is the gold standard for strength. It offers a tight, solid pattern that provides the best protection against cuts and abrasions. Some cheaper imitations might use a less durable weave pattern, which could put you at risk, especially in industrial or protective applications.

The Importance of Chainmail Inspection

Now that we’ve touched on the key pain points, let’s move on to the good stuff: how you can inspect chainmail like a pro. By understanding the basic factors that contribute to chainmail’s durability, you can avoid wasting money on low-quality products and ensure that your purchase meets the necessary safety standards.

Step-by-Step Guide to Inspecting Chainmail

-

Material Type (304 vs 316 Stainless Steel)

-

Check the product description or ask the seller about the steel grade.

-

304 stainless steel is ideal for decoration or light use, while 316 stainless steel is more resistant to corrosion and suitable for industrial or food handling environments.

-

Stainless steel is non-corrosive, but 316 offers better protection in harsh conditions like saltwater or food acids.

-

-

Ring Welding

-

Inspect the rings closely for visible welds. Welded rings will have a small seam or mark where the two ends of the ring meet. This is a good indication that the chainmail is built for durability.

-

Use a magnifying glass if necessarysometimes the weld might be subtle, but it’s still there!

-

-

Wire Thickness and Inner Diameter

-

Look for thick wires that feel substantial in your hand. Thin wires may bend or break more easily under stress.

-

The inner diameter of the rings should be consistent. Any rings that are too loose or too tight in the weave could compromise the strength and effectiveness of the chainmail.

-

-

Weave Patterns (European 4-in-1)

-

European 4-in-1 is the most common and strongest weave pattern used in chainmail. If the chainmail you’re inspecting follows this pattern, you’re looking at a product that should hold up well over time.

-

Check for uniformity in the pattern. Any irregularities could be a sign of poor craftsmanship.

-

-

Perform a Simple Pull Test

-

Gently tug on the rings to ensure they’re properly secured. A well-made chainmail piece should not pull apart easily. If you notice rings slipping or separating, it’s likely low-quality.

-

-

Check for Signs of Corrosion

-

If you notice any rust spots or discoloration, this is a red flag. Corrosion can weaken the chainmail and reduce its effectiveness.

-

Properly made stainless steel chainmail should be resistant to rust and corrosion, but low-grade or poorly welded chainmail can succumb to damage much faster.

-

Practical Tips for Buying Chainmail

-

Industrial Use: For tasks that involve handling sharp objects or machinery, like cut-resistant gloves or clothing for factory workers, always go for 316 stainless steel. The durability and resistance to corrosion will be worth the investment.

-

Food Handling: If you need chainmail for food processing or butchery, ensure it’s made from 316 steel. This will resist rust and bacteria buildup, making it ideal for food safety.

-

Cosplay: For decorative purposes, 304 stainless steel is usually enough. However, even for cosplay, make sure the weave is tight, the rings are welded, and the overall construction is solid.

-

Historical Replicas: Historical chainmail replicas should follow the European 4-in-1 weave for authenticity and strength. If you’re a reenactor, this is the standard you’ll want to look for.

Conclusion: How to Ensure You’re Buying Quality Chainmail

When purchasing chainmail, always remember: you get what you pay for. By following the inspection tips I’ve shared, you can easily spot the difference between high-quality, durable chainmail and cheaper, low-grade imitations. Whether you’re buying for industrial use, cosplay, or historical reenactments, it’s essential to know what you’re looking for to make an informed purchase.

I highly recommend following these steps to ensure that any chainmail you buy meets safety and durability standards. By checking the material, inspecting the welds, and evaluating the weave, you’ll save yourself time, money, and potential safety risks down the road.

To learn more about identifying high-quality chainmail products, check out our detailed chainmail inspection guide today!

FAQ

1. How can I tell if a chainmail ring is welded or open?

Look for a visible seam or mark where the two ends of the ring meet. Welded rings will have a solid bond, while open rings may show a gap or no visible seam at all.

2. Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel is the best choice for durability and corrosion resistance, especially in industrial or food-handling environments. 304 steel is suitable for decorative use.

3. How do I inspect the weave pattern for strength?

Check if the chainmail follows the European 4-in-1 weave pattern. This is a strong, consistent weave that provides the best protection.

4. What are the signs of low-quality or unsafe chainmail?

Look for signs of corrosion, loose rings, poor welding, and inconsistent weave patterns. These are indications of low-quality construction.

5. Can decorative chainmail be used for protective purposes?

While decorative chainmail made from 304 stainless steel can look great, it’s not as durable or safe for protective uses. For protection, choose 316 stainless steel and welded rings.

6. How do I choose the right chainmail for industrial vs cosplay use?

For industrial use, go with 316 stainless steel and a European 4-in-1 weave for maximum durability and safety. For cosplay, 304 stainless steel and decorative weaves may suffice.

Tags

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability