Chainmail Aprons for High-Speed Production Lines

Chainmail Aprons for High-Speed Production Lines: How to Choose Quality Chainmail for Safety and Durability

When working in high-speed production environments, especially in industries like food processing or manufacturing, safety is non-negotiable. One piece of safety equipment that is often overlooked but critical to preventing serious injuries is the humble chainmail apron. However, not all chainmail is created equal. As a buyer, collector, or industrial user, identifying high-quality chainmail that meets safety and durability standards can be a challenge. But fear nottoday, I’ll walk you through how to spot top-tier chainmail and avoid the common pitfalls that can lead to unsafe or unsatisfactory products.

Understanding the Challenge of Choosing Quality Chainmail

Imagine you’re working on a high-speed production line, slicing and dicing ingredients for hours. The last thing you want is to risk a severe hand injury due to subpar protective gear. This scenario is all too real for many industrial workers who rely on chainmail for cut protection. However, distinguishing between a high-quality, durable chainmail apron and one that’s just good for display or cosplay can be tricky.

The struggle lies in the nuances of chainmail constructionwelded rings versus open rings, material grades, and weave patterns all play a part in the final product’s strength and reliability. Without knowing what to look for, you could easily end up with a product that falls short of the protection you need.

In this guide, I’ll help you navigate these complexities and ensure that any chainmail you buy is safe, durable, and fit for the job.

Common Pain Points When Evaluating Chainmail

As a seasoned buyer or industrial user, I’ve encountered some common pain points when it comes to choosing chainmail products. Let’s dive into a few of the most frequent challenges:

1. Welded Rings vs. Open Rings

One of the most crucial aspects of chainmail quality is the type of rings used in the construction. Welded rings provide superior durability and safety, while open rings are often weaker and prone to breaking under stress. The problem? Many lower-quality products use open rings, making them more prone to wear and tear, especially in demanding environments.

2. Uncertainty About Material Quality (304 vs. 316 Stainless Steel)

When it comes to stainless steel, not all grades are created equal. Grade 304 stainless steel is widely used in chainmail, but it’s less resistant to corrosion and wear compared to the superior 316 grade. For industrial applications, especially in food processing, corrosion resistance is paramount. Choosing the right grade can mean the difference between a product that lasts for years and one that degrades quickly.

3. Weak or Inconsistent Weaves

The weave pattern is another critical factor when it comes to chainmail durability. Weave patterns like the European 4-in-1 are known for their strength and flexibility. However, some manufacturers may cut corners with inconsistent weaves, making the final product weaker and more prone to failure. As a buyer, you need to be vigilant when evaluating the weave to ensure you’re getting the strength you need.

How to Evaluate Chainmail Quality

Evaluating chainmail isn’t as complicated as it may seem. With a few key inspection methods, you can quickly determine whether a product is up to par. Here’s how you can evaluate the most important aspects of chainmail quality:

1. Check the Material Type (304 vs. 316 Stainless Steel)

The first thing you should do when inspecting chainmail is to check the material. For industrial use, particularly in environments that involve food handling or exposure to moisture, 316 stainless steel is the ideal choice. It’s highly resistant to corrosion and is much more durable than 304 stainless steel, which is more prone to rusting and degradation in harsh conditions.

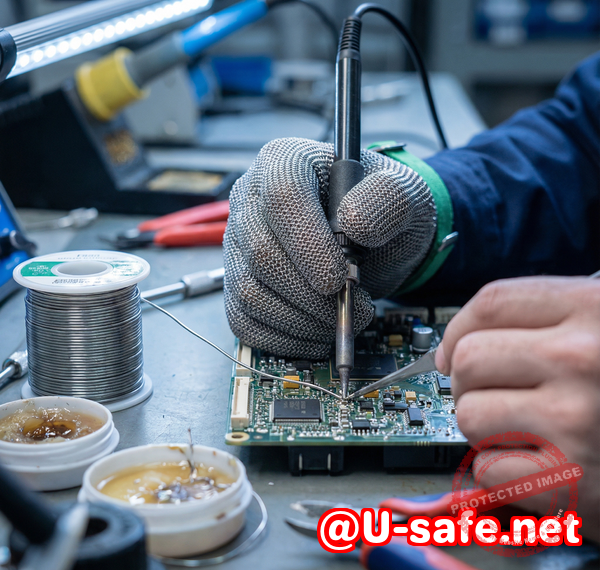

2. Inspect Ring Welding

Next, look closely at the rings themselves. Are they welded or open? High-quality chainmail uses welded rings, which are stronger and more reliable than open rings. You can usually spot the difference by looking for a visible seam or weld around the edge of the ring. If the ring looks smooth all the way around, it’s likely an open ring, which could compromise the integrity of the product.

3. Evaluate Wire Thickness and Ring Diameter

The thickness of the wire and the inner diameter of the rings are important factors that influence both the strength and comfort of chainmail. Generally, thicker wire and smaller rings provide better protection. Look for a product that features a wire thickness of at least 1.5mm and a ring diameter that’s proportional to the wire thickness. The smaller the gap between rings, the stronger the weave.

4. Examine the Weave Pattern

The weave pattern can also reveal a lot about the chainmail’s durability. The European 4-in-1 weave, for example, is widely recognized for its strength and flexibility. This means each ring is connected to four others in a specific pattern, creating a tight, interlocking structure. When inspecting a chainmail product, ensure that the weave is tight and uniformany irregularities could be a sign of poor craftsmanship.

Benefits of Proper Inspection

By taking the time to properly inspect the chainmail before purchase, you can avoid a range of problems. Here are just a few of the benefits of ensuring the product is up to scratch:

-

Avoid Unsafe Products: Whether you’re buying chainmail for industrial use, food processing, or cosplay, the last thing you want is a product that could fail during use. By focusing on material quality, ring welding, and weave strength, you can ensure the product will hold up under stress.

-

Ensure Durability: High-quality chainmail products are built to last. Proper inspection will help you choose a durable product that will stand the test of time, saving you money in the long run by avoiding frequent replacements.

-

Save Money: It’s easy to be tempted by cheaper chainmail options, but often, these are low-quality products that won’t offer the protection you need. By knowing what to look for, you can avoid wasting money on subpar products and invest in a chainmail apron or suit that will deliver value.

Practical Tips and Step-by-Step Guidance for Inspection

To help you feel more confident in your chainmail inspection, here are some quick tips to follow:

-

Pull Test: Gently pull on the rings to see if they hold together. If they feel loose or if any rings come apart, it’s a sign of poor construction.

-

Corrosion Check: Examine the chainmail for any signs of rust or corrosion, especially if it’s made from 304 stainless steel. If you spot any, it’s best to avoid the product altogether.

-

Weave Uniformity: Run your fingers along the weave to check for consistency. The rings should be evenly spaced, and the pattern should be tight without any loose or dangling rings.

Conclusion: Why Quality Matters

In conclusion, the quality of chainmail is paramount, whether it’s for industrial use, cosplay, or historical reenactments. By following the steps I’ve outlinedchecking the material, inspecting the welding, evaluating the wire thickness and weave patternyou can ensure that the chainmail you purchase will offer both safety and durability.

I highly recommend following these steps to ensure that any chainmail you buy meets safety and durability standards. Don’t settle for subpar productstake the time to inspect and evaluate your options carefully. Your safety, and the longevity of your gear, depend on it.

Learn more about identifying high-quality chainmail products: Aegimesh Chainmail Inspection Guide

Frequently Asked Questions

1. How can I tell if a chainmail ring is welded or open?

Welded rings will have a visible seam or weld mark around the edge, while open rings will be smooth all the way around.

2. Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel is the best choice for durability and corrosion resistance, particularly in industrial or food processing environments.

3. How do I inspect the weave pattern for strength?

Look for tight, uniform weaves like the European 4-in-1. The rings should interlock neatly with no gaps or irregularities.

4. What are the signs of low-quality or unsafe chainmail?

Look for loose or broken rings, signs of rust or corrosion, and uneven or inconsistent weave patterns.

5. Can decorative chainmail be used for protective purposes?

Decorative chainmail is usually weaker and less durable. For safety purposes, always choose chainmail designed for protection, with welded rings and the appropriate weave.

6. How do I choose the right chainmail for industrial vs. cosplay use?

For industrial use, look for chainmail made from 316 stainless steel with welded rings and a strong, tight weave. For cosplay, you can opt for lighter, decorative chainmail, but ensure it meets your durability needs.

Tags or Keywords

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability