Chainmail The Armor That Shaped History

Chainmail The Armor That Shaped History

Discover how to identify high-quality chainmail by inspecting welded rings, stainless steel grades, and weave strength so you can avoid unsafe purchases and invest with confidence.

The first time I tried to buy chainmail, I thought it would be simple. I needed something sturdy, something that looked authentic, and something I could actually trust. Like many buyers, I scrolled through dozens of product photos, read vague descriptions, and wondered, “How do I really know if this chainmail is any good?” The rings all looked similar. The prices varied wildly. And the reviews? Often written by people who had never put the product to real use.

That confusion is more common than most sellers like to admit. Whether you are buying chainmail for industrial cut protection, food processing, cosplay, or a historical display, the quality difference between a well-made piece and a decorative imitation can be enormous. I have seen chainmail fail under light pressure, rust within weeks, or pull apart because the rings were never welded properly. On the other hand, I have also handled chainmail that felt reassuringly solid, flexible without being fragile, and clearly designed for professional use.

This is why learning how to evaluate chainmail quality matters so much. It is not just about looks. It is about safety, durability, and value for money.

One of the biggest pain points I hear from buyers is the difficulty of telling welded rings from open rings. At a glance, they can look almost identical, especially in online photos. Open rings are cheaper and easier to produce, which makes them popular in low-quality or decorative chainmail. The problem is that open rings can spread under pressure. I once tested a budget chainmail glove that looked impressive on arrival. A gentle pull test caused several rings to open instantly. That might be acceptable for costume wear, but it is completely unsafe for cut-resistant chainmail or industrial use.

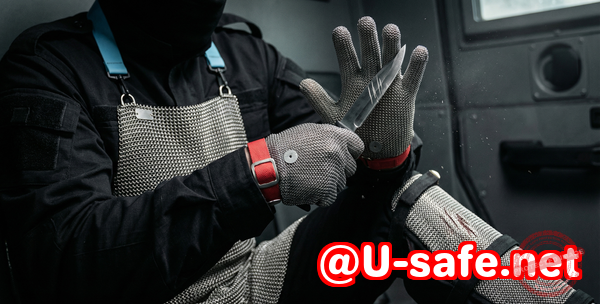

A simple inspection can save you from that mistake. Hold the chainmail close to a light source and examine the rings carefully. Welded rings will show a smooth, closed joint, often with a faint weld line. Open rings usually have a visible gap or overlapping ends. If you can slip a fingernail into the joint, it is not welded. High-quality stainless steel chainmail almost always uses welded rings for a reason: strength and reliability.

Another common challenge is understanding stainless steel grades. Many listings simply say “stainless steel chainmail” without specifying the grade. That lack of detail should raise a red flag. In real-world use, the difference between 304 and 316 stainless steel matters. I learned this the hard way when a piece of chainmail used near moisture started showing corrosion spots after a few months.

304 stainless steel is widely used and offers good corrosion resistance for general environments. It is suitable for many applications, including cosplay, display, and light industrial use. 316 stainless steel, however, includes molybdenum, which significantly improves resistance to corrosion, especially in salty or wet environments. For food processing, marine settings, or heavy-duty cut-resistant chainmail, 316 is usually the better choice.

When evaluating a product, do not be shy about asking the seller which grade they use. Reputable manufacturers, such as those behind Aegimesh Chainmail, make this information clear because it reflects confidence in their materials. If the answer is vague or evasive, that is often a sign of lower quality.

Weave consistency is another area where buyers struggle. The weave pattern affects not only how chainmail looks, but how it performs under stress. One of the most trusted patterns for strength and durability is the European 4-in-1 weave. Each ring passes through four others, distributing force evenly across the surface. This is why it has been used for centuries, from historical armor to modern cut-resistant chainmail.

I once compared two pieces side by side: one using a loose, inconsistent weave, and another using a tight European 4-in-1 pattern. The difference was obvious the moment I handled them. The loose weave felt floppy and uneven. The tighter weave moved smoothly but resisted deformation when pulled. That tactile feedback is something you can learn to recognize quickly.

When inspecting a weave, look for uniformity. Rings should sit evenly, without gaps or twisted sections. Inconsistent spacing often indicates rushed manufacturing or poor quality control. For professional or safety-critical use, that inconsistency can become a failure point.

Wire thickness and ring diameter also play a huge role in chainmail durability. Thicker wire generally means stronger chainmail, but it also affects flexibility and weight. Thin wire can be acceptable for decorative or cosplay use, but it is rarely suitable for cut-resistant applications. Inner diameter matters too. Rings that are too large relative to the wire thickness can deform more easily under load.

A practical tip I always share is the simple pull test. Lay the chainmail flat and gently pull it in opposite directions. You are not trying to break it, just to feel how it responds. High-quality chainmail will resist evenly, with no sudden stretching or popping sounds. If rings start to open or the weave distorts noticeably, that is a warning sign.

Corrosion is another giveaway of poor craftsmanship or unsuitable materials. Even stainless steel chainmail can corrode if the wrong grade is used or if the surface finish is poor. Look for discoloration, rough patches, or residue. These can indicate improper alloy selection or contamination during manufacturing. For chainmail intended for food handling or industrial environments, corrosion is not just cosmetic. It can be a serious hygiene and safety issue.

This is where having a clear reference point helps. I often point buyers to the Aegimesh Chainmail inspection approach because it breaks down these checks into simple, understandable steps. Instead of relying on marketing claims, you learn how to verify material type, inspect welded rings, measure wire thickness, and assess weave patterns like European 4-in-1 for real-world strength.

Understanding these factors brings real benefits. You avoid unsafe chainmail that could fail during use. You ensure that decorative or cosplay pieces meet your expectations for durability. And perhaps most importantly, you save money by identifying low-quality products before they end up unused in a drawer.

Choosing the right chainmail also depends on how you plan to use it. Industrial cut protection requires welded rings, appropriate wire thickness, and often 316 stainless steel for corrosion resistance. Food processing demands smooth finishes and hygienic materials. Cosplay and historical replicas may prioritize appearance, but even then, durability matters if the piece will be worn repeatedly. Collectors often want authenticity, which includes correct weave patterns and materials.

I remember a cosplayer friend who bought a bargain chainmail shirt online. It looked great in photos, but after one convention weekend, several sections had stretched beyond repair. Had they known how to inspect ring welds and weave consistency, they could have avoided that disappointment entirely.

At the end of the day, chainmail quality is not a mystery reserved for experts. With a bit of guidance and hands-on inspection, anyone can learn to spot the difference between professional-grade stainless steel chainmail and fragile imitations. I highly recommend following these steps to ensure any chainmail purchase meets safety and durability standards.

If you want to go deeper, learn more about identifying high-quality chainmail products: https://www.aegimesh.com/

Check out our detailed chainmail inspection guide today and make your next purchase with confidence.

Frequently Asked Questions

How can I tell if a chainmail ring is welded or open?

Examine the joint closely under good light. Welded rings have a smooth, closed seam. Open rings show a visible gap or overlapping ends.

Which stainless steel grade is best for long-lasting chainmail?

For general use, 304 stainless steel is common and reliable. For wet, salty, or food-processing environments, 316 stainless steel offers better corrosion resistance.

How do I inspect the weave pattern for strength?

Look for uniform spacing and consistency. A European 4-in-1 weave is a strong, proven pattern. Perform a gentle pull test to feel how evenly the force is distributed.

What are the signs of low-quality or unsafe chainmail?

Open rings, inconsistent weave, visible corrosion, very thin wire, and vague material descriptions are all red flags.

Can decorative chainmail be used for protective purposes?

Usually not. Decorative chainmail often uses open rings and thinner wire, making it unsuitable for cut-resistant or industrial applications.

How do I choose the right chainmail for industrial vs cosplay use?

Industrial use requires welded rings, proper wire thickness, and suitable stainless steel grades. Cosplay can focus more on appearance, but durability still matters for wearability.

Tags and Keywords

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability