EN 1082 and Its Application in Modern Chainmail Fashion

EN 1082 and Its Application in Modern Chainmail Fashion

When you’re in the market for chainmail, whether it’s for protective purposes, cosplay, or even historical replicas, the process of identifying quality can feel overwhelming. There are so many variables to consider: the material, the craftsmanship, the durability, andperhaps most importantthe safety. Have you ever found yourself staring at a chainmail product, unsure if it’s the right fit for your needs, or worse, unsure if it’s actually safe to use? It’s a frustrating experience, but you’re not alone.

For years, I struggled with this exact problem. Chainmail is often sold in a variety of forms, from industrial protection gear to decorative cosplay pieces. And while they all may look similar, not all chainmail is created equal. Some are made with subpar materials or flawed craftsmanship, which could lead to safety hazards or just poor performance. So, how do you ensure that what you’re buying is genuinely high-quality? It all comes down to knowing what to look for, which is where EN 1082 and the Aegimesh Chainmail guide come into play.

Understanding EN 1082 and Why It Matters

EN 1082 is a set of European standards that provide guidelines for protective chainmail used in various industries. These standards assess the materials, construction, and effectiveness of chainmail, particularly in protective settings like industrial workplaces or food processing. The goal is simple: ensure the product meets specific safety and durability benchmarks.

While EN 1082 applies primarily to industrial-grade chainmail, its principles also apply to any high-quality chainmail, whether you’re using it for cosplay or historical reenactments. If you’re looking to invest in chainmail, understanding EN 1082 is crucial for distinguishing between genuine protective quality and decorative or low-grade products.

But, how do you apply this knowledge when purchasing chainmail? Let’s break it down.

Common Problems When Evaluating Chainmail

1. Difficulty Identifying Welded Rings vs. Open Rings

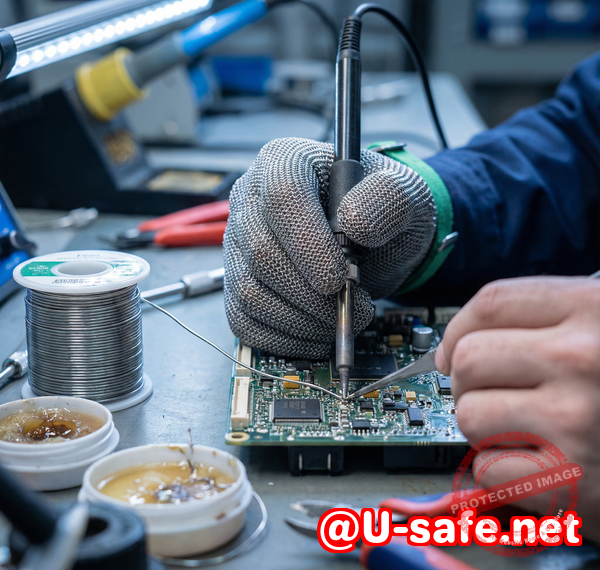

One of the first things you need to check when evaluating chainmail is the type of rings used in its construction. Rings are either welded or open. Open rings are weaker and more prone to breakage, especially when used for industrial purposes like cut protection. Welded rings, on the other hand, provide much better durability and safety. But how can you tell the difference?

It’s actually pretty simple once you know what to look for. Welded rings will show a small, visible seam where the ring has been fused together. Open rings, however, have a gap that’s visible to the naked eye. A quick inspection can often tell you whether a chainmail product is safe or likely to fail under pressure.

2. Uncertainty About Stainless Steel Grades

Stainless steel is the go-to material for chainmail due to its strength, resistance to rust, and ability to withstand harsh conditions. But not all stainless steel is created equal. The two most common grades used in chainmail are 304 and 316.

-

304 Stainless Steel is durable and resistant to corrosion, making it a great choice for decorative or light-use chainmail (like cosplay).

-

316 Stainless Steel, however, is far superior in terms of corrosion resistance, especially in harsh environments (think industrial use, food processing, or marine applications).

So, how do you know which grade is right for your needs? It’s all about knowing your intended use. For industrial applications or food handling, you’ll want to go with 316 stainless steel. For lighter, decorative uses, 304 stainless steel will generally suffice.

3. Weak or Inconsistent Weaves

The weave pattern of chainmail also plays a significant role in its strength and durability. For example, the European 4-in-1 weave is one of the strongest and most common patterns used in both modern and historical chainmail. In this pattern, each ring is interwoven with four others, creating a dense, tight weave that offers maximum protection against cuts and abrasions.

A poor weave or an inconsistent pattern can seriously weaken the structure of the chainmail. If you notice that the rings are not tightly interwoven or that the weave pattern looks uneven, you may be dealing with a low-quality product that won’t perform well in protective settings.

How to Inspect Chainmail Quality

Now that we’ve identified some of the common pitfalls, let’s talk about how you can avoid them. Inspecting chainmail might seem daunting at first, but with a few simple steps, you can easily determine whether a product is high-quality or not.

1. Inspect the Material

Start by checking the material of the rings. If the product claims to be made from stainless steel, ensure that it’s either 304 or 316 grade. Look for the manufacturer’s information about the material and confirm it before making a purchase.

2. Check the Ring Welding

As mentioned earlier, welded rings are far superior to open rings. Look closely at the rings, especially where the ends meet. A welded ring will have a smooth, seamless appearance, while an open ring will have a small gap.

3. Measure the Wire Thickness and Ring Diameter

The wire thickness and ring diameter can make or break the strength of a chainmail product. If the wire is too thin or the rings are too large, the chainmail will lack the necessary strength to withstand cuts or abrasion. A simple measuring tape or caliper can help you assess the size of the wire and rings to ensure they meet the standards of quality chainmail.

4. Evaluate the Weave Pattern

Take a close look at the weave pattern, specifically European 4-in-1. If the weave looks uneven or sloppy, it could indicate poor craftsmanship, which can significantly reduce the durability and effectiveness of the chainmail.

5. Perform a Pull Test

One of the simplest and most effective ways to test chainmail durability is the pull test. Gently pull on a section of the chainmail to see if any rings come apart. If they do, it’s a clear sign that the chainmail is not strong enough for practical use. If the rings stay intact, the product is likely high-quality.

6. Check for Signs of Corrosion or Poor Craftsmanship

Even stainless steel can show signs of wear over time, but a good-quality product will resist corrosion and maintain its appearance. Check for any rust, pitting, or discolored areas that could indicate a low-quality product. Also, examine the overall craftsmanshiplook for jagged edges, uneven links, or loose rings.

7. Choose the Right Chainmail for the Job

Not all chainmail is created for the same purpose. If you’re purchasing chainmail for industrial use or cut protection, be sure to select a product that is specifically designed for those purposes. Decorative chainmail may look appealing for cosplay or historical reenactments, but it may not provide the protection or durability you need for heavy-duty tasks.

Conclusion: Making the Right Chainmail Choice

By following these simple steps, you can ensure that any chainmail you purchase meets the necessary safety and durability standards. From inspecting the material and welds to performing a pull test, these tips will help you make an informed decision and avoid low-quality products.

I highly recommend following these steps to ensure any chainmail purchase meets safety and durability standards. Whether you need chainmail for industrial protection, food handling, cosplay, or historical reenactments, proper inspection is the key to making the right choice.

If you’re unsure where to start, check out Aegimesh Chainmail’s guide and inspection tool. This guide offers a detailed breakdown of everything you need to know to assess chainmail quality, helping you avoid potential safety risks and wasted money.

Learn more about identifying high-quality chainmail products: Aegimesh Chainmail Guide

Check out our detailed chainmail inspection guide today.

FAQs

1. How can I tell if a chainmail ring is welded or open?

Look for a visible seam where the ends of the ring meet. A welded ring will have a smooth, seamless finish, while an open ring will show a small gap.

2. Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel is the most durable and corrosion-resistant, making it ideal for industrial or food-processing applications. 304 stainless steel is good for decorative or light-use chainmail.

3. How do I inspect the weave pattern for strength?

Look for a tight, even weave, such as the European 4-in-1 pattern. Any inconsistencies in the weave can weaken the chainmail and compromise its protection.

4. What are the signs of low-quality or unsafe chainmail?

Look for weak or inconsistent welds, thin wire, uneven weave patterns, signs of corrosion, or gaps in the rings. Poor craftsmanship is often a sign of low-quality chainmail.

5. Can decorative chainmail be used for protective purposes?

Generally, no. Decorative chainmail is made with lighter materials and may not meet the durability standards required for protection. Always choose industrial-grade chainmail for safety.

6. How do I choose the right chainmail for industrial vs cosplay use?

For industrial use, choose chainmail made from 316 stainless steel with a durable weave like European 4-in-1. For cosplay, 304 stainless steel and decorative weaves can be sufficient.