Why EN 1082 Sets the Standard for Cut-Resistant Chainmail Gear

Why EN 1082 Sets the Standard for Cut-Resistant Chainmail Gear

When purchasing chainmail for protection, cosplay, or historical reenactments, it can often feel like you’re navigating a labyrinth of options. How can you be sure that what you’re buying is high-quality, safe, and durable? How do you avoid falling for a low-grade, unsafe chainmail product that could potentially compromise your safety or fail to meet your expectations? If you’ve found yourself wondering these very questions, you’re not alone. As someone who has spent years exploring the world of chainmail, I know how easy it is to be misled by flashy marketing or shiny, misleading features.

Luckily, there’s a simple and proven way to cut through the noise: EN 1082, a European standard that sets the bar for cut-resistant chainmail gear. In this guide, we’ll take a deep dive into why this standard is so important and how it can help you identify high-quality chainmail products, whether you’re a buyer, collector, or industrial user. I’ll walk you through practical inspection tips, easy ways to identify key material features, and how to ensure you’re choosing the right chainmail for your needs.

Understanding EN 1082: The Gold Standard for Cut-Resistant Chainmail

EN 1082 is a set of standards that govern the quality and performance of protective chainmail, particularly in relation to its ability to resist cutting. It covers everything from the material used to construct the rings to the way they’re woven and assembled. For anyone in industries like food handling, manufacturing, or even those looking for high-quality cosplay or historical chainmail, understanding these standards is crucial.

Why Should You Care About EN 1082?

Whether you’re using chainmail to protect your hands in a food processing facility, create a stunning historical replica for a movie, or wear it as part of a medieval armor set, knowing that your gear is made according to a proven, tested standard can make all the difference.

But why does it matter? Let’s look at some common issues you might face without the EN 1082 standard:

-

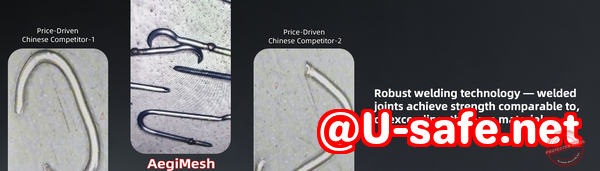

Weak Welds: If you’re buying chainmail to protect yourself from cuts, poor welds can be a serious problem. Weak welds can lead to rings breaking, rendering the entire piece useless.

-

Inconsistent Weave: Poor weave patterns not only affect the aesthetic but also reduce the protective strength of the chainmail. Inconsistent weaves could expose gaps that make your chainmail less cut-resistant.

-

Inferior Materials: Using lower-grade stainless steel or even non-stainless materials can cause the chainmail to rust, degrade quickly, or not provide the level of protection you’re looking for.

EN 1082 ensures that chainmail products are built with consistency, reliability, and durability in mind, ensuring they meet the protection standards needed for industrial use and safe wear.

How to Inspect Chainmail Quality: A Step-by-Step Guide

When you’re shopping for chainmail, it’s important to be able to differentiate between a high-quality piece and a cheaply made product that could fall apart after only a few uses. Here’s how to assess chainmail gear:

1. Check the Material: Stainless Steel Matters

The first step in evaluating your chainmail is ensuring that it’s made from the right materials. For top-tier protection, you want stainless steelpreferably grades 304 or 316.

-

304 Stainless Steel: This is a versatile, corrosion-resistant option that works well for non-industrial applications like cosplay or historical reenactments.

-

316 Stainless Steel: If you need chainmail for industrial or food processing use, this is your best bet. It offers even greater corrosion resistance and durability.

When inspecting a chainmail piece, look for the grade if it’s labeled, or ask the seller for specifics. If you’re uncertain about the material’s authenticity, feel free to do a quick test using a magnet304 will show slight attraction, while 316 is non-magnetic.

2. Welded Rings vs. Open Rings

A common issue that buyers face is distinguishing between welded rings and open rings. This is one of the easiest ways to determine the quality of your chainmail.

-

Welded Rings: These rings are made by heating the ends of the wire and fusing them together. This creates a more secure and durable piece of chainmail, as the rings stay closed under stress. High-quality chainmail should always feature welded rings, especially for protective uses.

-

Open Rings: Cheap chainmail might feature open rings that are not welded, leaving the rings prone to coming apart over time. This can significantly reduce the durability of your chainmail.

3. Wire Thickness and Ring Diameter

The thickness of the wire and the diameter of the rings are also critical to chainmail quality. Thicker wires and smaller ring diameters generally provide better protection.

-

Wire Thickness: Check the thickness of the wire used to form the rings. A good-quality chainmail piece should have a wire thickness that’s substantial enough to resist breaking under pressure.

-

Ring Diameter: The inner diameter of the rings should be small enough to create a strong weave pattern, which contributes to the chainmail’s overall strength.

4. Evaluate the Weave Pattern: European 4-in-1

A crucial part of chainmail is the weave pattern. For maximum strength and flexibility, a European 4-in-1 weave is often recommended. This pattern involves each ring being passed through four others, which creates a tight, robust weave that maximizes protection.

-

Check the Tightness of the Weave: A loose weave can cause gaps that compromise the chainmail’s ability to resist cuts or damage.

-

Pattern Consistency: Make sure the weave is uniform and even across the entire piece. A consistent, tightly woven pattern indicates craftsmanship and quality.

5. Pull Test for Durability

If you’re still unsure about the durability of the chainmail, the pull test is an easy and effective way to check. Gently pull on the rings at the edges of the weave. High-quality chainmail should resist stretching or pulling apart. If the rings bend or come apart easily, this is a sign that the chainmail is poorly constructed.

6. Look for Corrosion or Rust

One of the major red flags when inspecting chainmail is signs of corrosion. If you’re purchasing for industrial or food handling purposes, rust can be dangerous, as it may contaminate the product or compromise its protective abilities.

-

Signs of Rust: Any visible discoloration or flaking indicates corrosion.

-

Preventative Maintenance: Stainless steel chainmail, if well-maintained, should resist rust. However, regular cleaning and inspection are key to ensuring the chainmail stays in top condition.

7. Choose the Right Chainmail for Your Use

The type of chainmail you choose will depend on your specific needs:

-

Industrial Use: If you’re buying chainmail for cut protection in industrial settings, opt for 316 stainless steel with a tight, durable weave like European 4-in-1.

-

Cosplay or Display: For decorative uses like cosplay, a slightly lighter weave may suffice, but it should still meet quality standards for material and construction.

-

Food Processing: In this environment, you’ll need chainmail that can resist not only cuts but also bacteria and corrosion. Ensure your chainmail is made of high-quality stainless steel with a tight weave.

Conclusion: How to Choose the Best Chainmail

After following these inspection tips, I highly recommend you follow these steps to ensure any chainmail purchase meets safety and durability standards. Remember to always check the material, inspect the welds, evaluate the wire thickness, and ensure the weave pattern is tight and consistent. Doing so will save you money and ensure that the chainmail you buy provides the level of protection you’re looking for.

Want to learn more about identifying high-quality chainmail products? Check out Aegimesh’s detailed inspection guide today at www.aegimesh.com.

Frequently Asked Questions (FAQ)

-

How can I tell if a chainmail ring is welded or open?

Inspect the ring closely. A welded ring will have no gap, while an open ring will have a visible space where the ends meet.

-

Which stainless steel grade is best for long-lasting chainmail?

316 stainless steel is ideal for industrial and food processing environments due to its superior corrosion resistance.

-

How do I inspect the weave pattern for strength?

Look for a consistent European 4-in-1 pattern. Each ring should pass through four others tightly, ensuring durability and cut resistance.

-

What are the signs of low-quality or unsafe chainmail?

Weak welds, inconsistent weave patterns, signs of rust, and the use of inferior materials like non-stainless steel are all indicators of poor quality.

-

Can decorative chainmail be used for protective purposes?

While it may look visually appealing, decorative chainmail may not offer the same level of protection as a properly constructed piece designed for safety.

-

How do I choose the right chainmail for industrial vs cosplay use?

For industrial use, choose heavy-duty chainmail with 316 stainless steel and tight weaves. For cosplay, lighter materials like 304 stainless steel may suffice.

Tags or Keywords

chainmail quality, welded rings, stainless steel chainmail, cut-resistant chainmail, chainmail inspection, European 4-in-1 weave, chainmail durability