How to Discern the Genuine Quality of Chainmail Products

In the marketplace, chainmail products often appear outwardly alike; however, their welding integrity, raw materials, and longevity may vary considerably. To assist clients in making a more informed and objective assessment, we have outlined the essential criteria that merit close attention when selecting chainmail products.

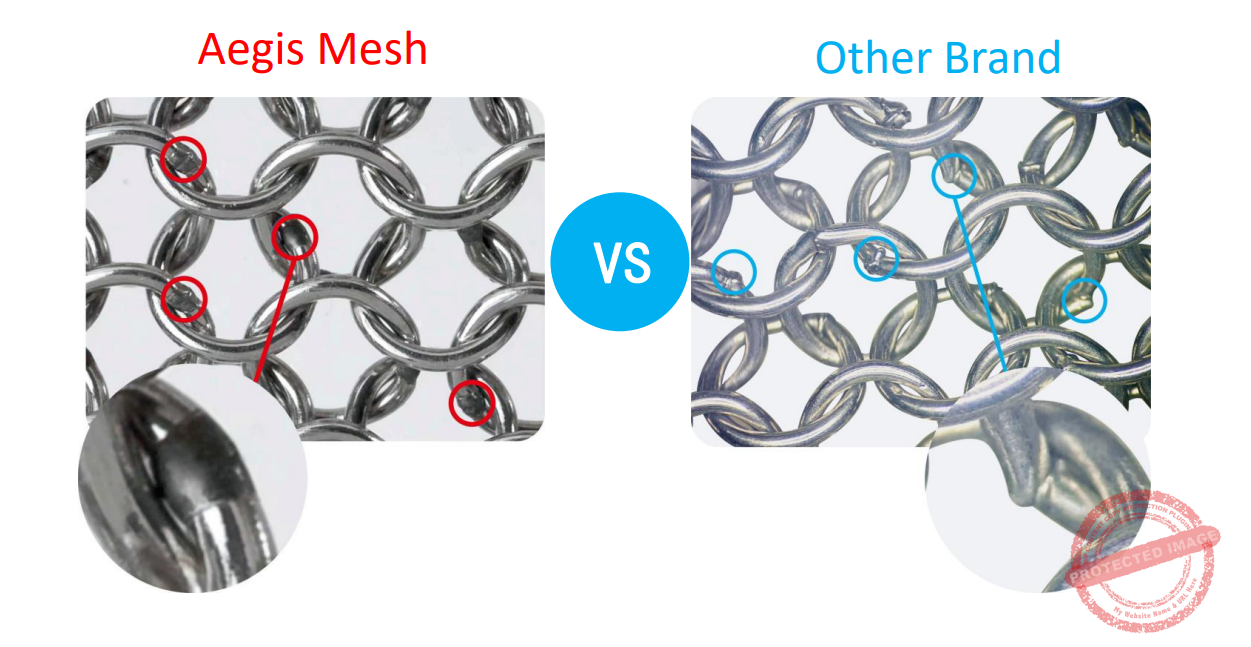

1. The Quality of the Welded Joints – The Principal Determinant of Longevity

The welded closure of each ring directly influences the chainmail’s resistance to tearing, its overall durability, and, most importantly, its safety.

- High-quality chainmail: The welds are evenly sealed, with no weak fusion and no latent gaps.

- Inferior chainmail: The welds are insecure, making the rings prone to splitting or detaching during use.

Our Distinct Advantage:

We employ precision micro-beam plasma welding technology from Castolin Eutectic (Germany) and Air Liquide (France). This ensures that the strength of each welded joint is equal to—or indeed surpasses—that of the base material.

Every production batch undergoes tensile testing to verify reliability and structural integrity.

2. Smooth, Burr-free Welds – The Foundation of Wearing Comfort

Any residual burrs left after welding can scratch the skin or snag clothing during use, causing discomfort and unnecessary risk.

Superior chainmail: Welded joints are smooth and refined, with no sharp sensation to the touch.

Ordinary chainmail: Welds are coarse, the edges rigid, often leading to localised discomfort or damage to garments.

Our Distinct Advantage:

Following welding, each piece undergoes several stages of meticulous polishing and surface finishing, ensuring every point of contact is rounded, gentle, and refined to the touch.

3. Flawless Welds – Ensuring Safety and Reliability

Welds that appear intact may, in reality, be imperfect, and under actual tensile stress, they can fail suddenly, posing potential hazards or interrupting use.

Our Approach:

Every batch undergoes 100% structural inspection of all welded joints.

Randomised multi-point tensile testing is conducted to confirm strength.

Batch numbers are fully traceable, allowing complete verification of provenance.

This rigorous protocol ensures that every piece we produce delivers verifiable reliability and uncompromised safety.

4. Extended Lifespan and Reduced Maintenance Costs

High welding strength + Smooth finishing + Flawless welds

= Significantly prolonged service life, even under frequent and demanding use—be it in slaughterhouses, protective applications, training, or exhibitions.

This not only enhances the user experience but also diminishes the need for frequent replacements, thereby reducing long-term costs.

5. Quick Self-Inspection Methods for Users

If you are in the process of evaluating potential suppliers, we warmly invite you to contact us for:

- Samples

- Weld Strength Test Reports

- Traceable Batch Quality Inspection Data

WhatsApp: 00351-934290243

Email: metalglove@u-safe.net ;metalmesh@u-safe.net

We encourage you to liaise with our technical team, who can also assist in establishing quality standards tailored to your specific application requirements.